Kubota will be at CONEXPO at Booth S84415.

Kubota’s drive towards a carbon-neutral future encompasses a range of recently-launched, groundbreaking engines including new hybrid and hydrogen models along with the expanding use of more low-carbon alternative fuels.

Micro Hybrid Technology is one key initiative for Kubota and is a system installed with a 48-volt motor generator using electric power only when intermittent overloads need to be handled. A motor-assist function is used to deliver an extra 10 kW of electrical boost power when needed for occasional sudden loads enabling operators to select an engine with output to match the load range, together with electric power to compensate for infrequent intermittent overloads.

Kubota Micro Hybrid Technology is particularly suitable for applications with occasional overloads such as non-highway machines used on work sites, forklifts, sweepers, road rollers, excavators, telehandlers, wheel loaders, generators and aerial lifts. It is also fit for purpose for use in indoor applications.

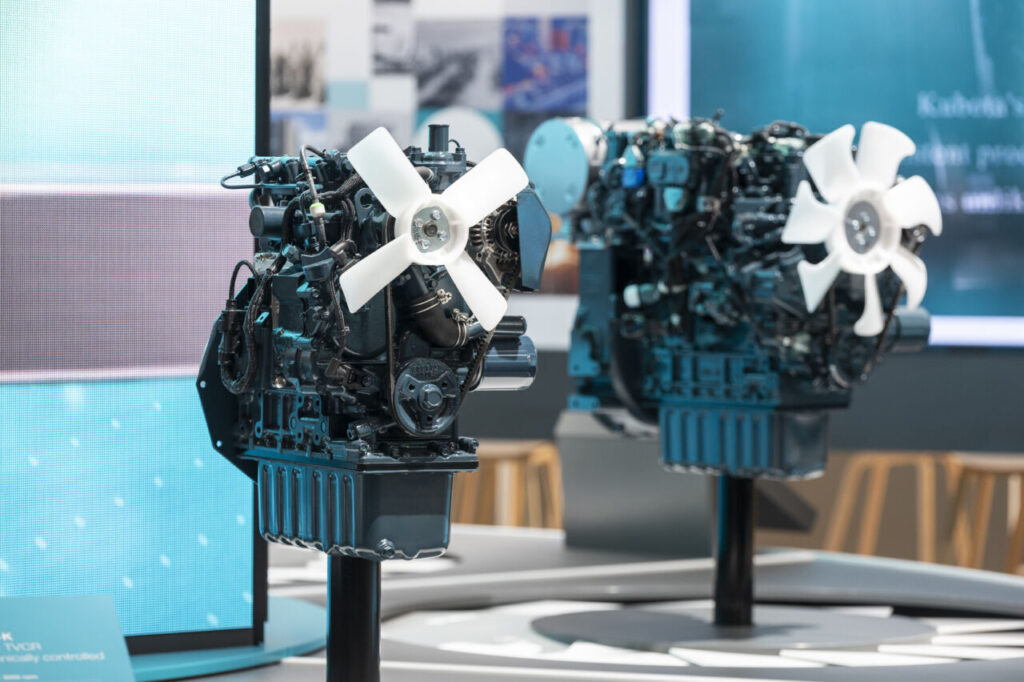

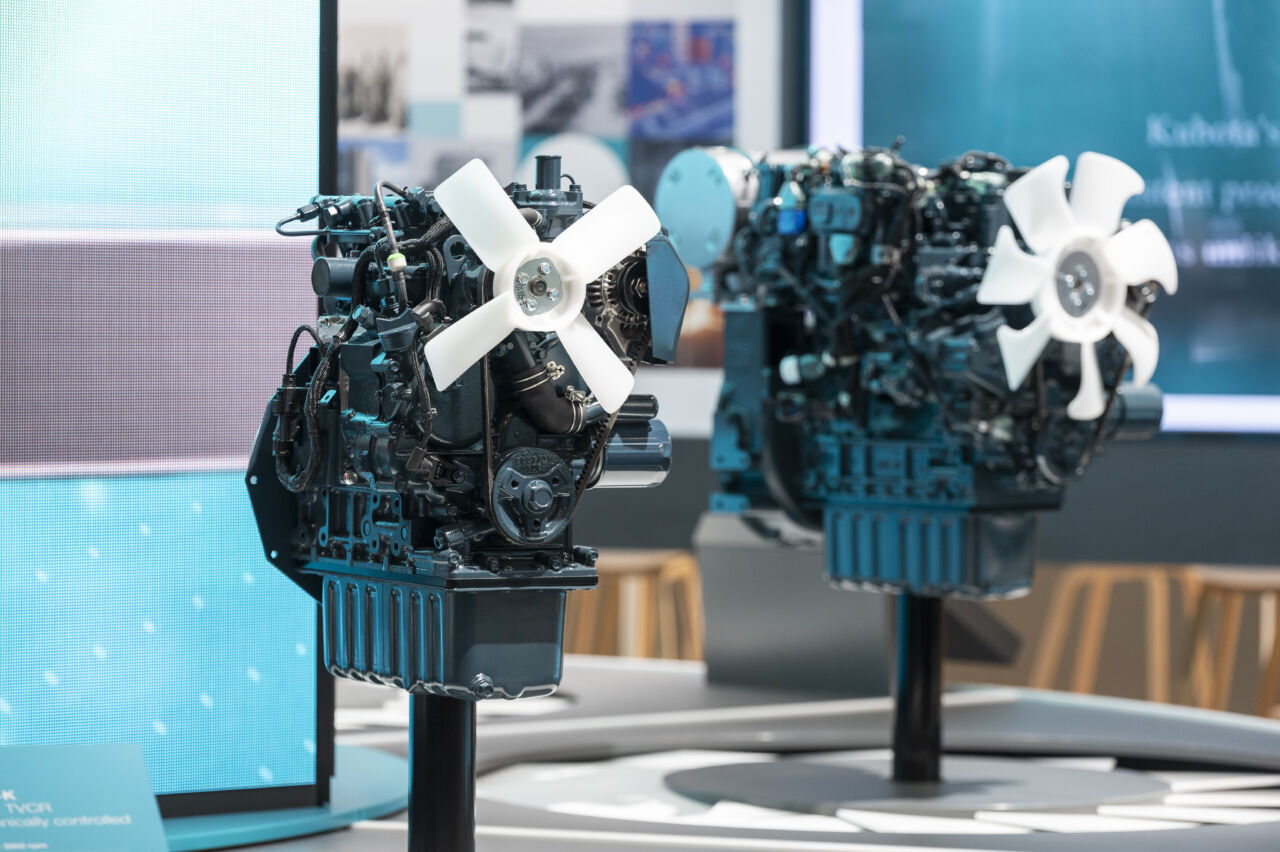

Two of the highlights of the expanded Kubota portfolio are the three-cylinder D1803 CR-T P1 and D1105 P2 micro hybrid engines which are both vertical, water-cooled, four-cycle diesels.

The compact D1803 CR-T P1 Hybrid has a rated output of 37.0 kW (49.6 HP) at 2700 rpm.

The AC synchronous motor generator, which does not require maintenance work, is encased in the flywheel housing keeping engine size to a minimum and all necessary components, such as motors and 48 V lithium ion batteries, are Kubota-supplied meaning customer development resources can be minimised. A belt drive mechanism is not required thus increasing robustness and ease of maintenance.

The 1.826 L displacement P1 has a bore and stroke of 87 x 102.4 mm, meets EPA/CARB Tier 4 and EU Stage lllB emission regulations and has a maximum torque of 150.5 Nm at 1600 rpm.

The P1 features a direct injection combustion system and a common rail fuel system.

The D1105 P2 Hybrid is rated at 18.5 kW (24.8 HP) at 3000 rpm and has a clutch positioned between the engine and the motor drive. The P2 can be switched between engine drive, motor drive and engine + motor drive while in operation depending on the application. For example, the engine can be stopped and switched to the electric motor in noise or emission-sensitive environments.

The engine is compact even with a one-way clutch which is incorporated in the supplied 20 cm wide gearbox which saves space compared to traditional combinations of engines and separately bought clutches thus, also, providing more flexibility for machine designers. A hydraulic pump can be mounted to the gearbox to take off power.

The 1.123 L displacement P2 has a bore and stroke of 78 x 78.4 mm, meets EPA/CARB Tier 4 (NRTC/NTE test mode) and EU Stage V emissions regulations and has a maximum torque of 71.5 Nm at 2200 rpm.

The P2 has an indirect injection combustion system and an in-line pump fuel system. Production of the P2 is scheduled for 2025.

From March 2023 three micro-hybrid systems are being promoted by Kubota – the new D1803 CR-T P1, the D1105 P2 and the V3307 P0.

The 3.331 L displacement four-cylinder, vertical, water-cooled, four-cycle Kubota V3307 P0 micro hybrid has a rated power of 55.4 kW at 2600 rpm. Bore and stroke is 94 x 120 mm and as the P0 is the same size as common rail engines it is easy to install. The engine meets EPA/CARB Tier 4 and EU Stage V emissions regulations.

Another key development by Kubota features the company’s advances with hydrogen engine technology – an attractive carbon-free alternative fuel solution.

The Kubota 3.8 L, 85 kW four-cylinder industrial off-highway hydrogen engine eliminates carbon dioxide emissions by only using hydrogen as a fuel.

Kubota’s hydrogen engine is based on the spark-ignited type WG3800 engine. By keeping the size or footprint of the existing engine, Kubota has maintained the variety of accessory selections and compatibility with customer applications. Also, the position of the Power Take Off has not changed. The Kubota hydrogen engine is an attractive choice within the generator set sector and is already attracting interest from manufacturers.

In another breakthrough, the company recently revealed that all Kubota diesel engines, including Stage V models, can use paraffin-based fuels that comply with European standard EN 15940. The newly approved fuels include Gas to Liquid (GTL) and Hydrotreated Vegetable Oil (HVO). The use of HVO has also recently been approved for Kubota diesel engines in the United States.

Emphasising Kubota’s commitment to a carbon-neutral future, HVO offers a range of environmental benefits compared with more conventional fuels. The “Drop-In” fuels do not require engine or machine modifications to enable their use.

Kubota has also taken the wraps off two new engines featuring state-of-the-art technology which expand the fully electronically controlled engine line-up below 19 kW and which enhance the company’s low carbon credentials.

The latest additions to the Kubota engine portfolio also include the D902-K and D1105-K engines which both feature Kubota’s highly advanced and ground-breaking common rail system developed exclusively for small engines, TVCR.

Characteristics of the new three-cylinder, vertical, water-cooled, four-cycle diesel engines include smokeless operation, less carbon emissions due to low fuel consumption, high performance at high altitude and stable support for machine operations. They meet regional emissions standards EPA Tier 4, Stage V and China IV.

For the D1105-K only an Electronically Controlled Unit can be installed directly onto the engine. In addition a new larger oil pan is a standard feature to extend the oil change interval periods, further reducing maintenance costs.

The common rail D902-K has a displacement of 0.898 L. Output (Gross kW/rpm) is 18.5/3600; 16.5/3200 and 13.4/2600. Torque (Gross Nm/rpm) is 56.1/2600; 56.1/2400 and 55.2/2400. Dry weight is 72 kg.

The common rail D1105-K has a displacement of 1.123 L. Output (Gross kW/rpm) is 18.5/3000 and torque (Gross NM/rpm) is 72.4/2200. Dry weight is 93 kg.

As the engines are electronically controlled they can communicate via Controller Area Network (CAN) which means engine operating data, needed for remote monitoring of performance, can be acquired.

The introduction of the highly efficient vertical, water-cooled, four cycle Kubota 09 Series V5009 marked the company’s first-ever diesel engine above 200 HP and is designed to meet the higher power requirements and wide range of needs in construction and industrial machines.

The V5009 can deliver up to 157.3 kw (210.9 HP) at 2200 rpm while meeting the emissions standards of EPA/CARB Tier 4 and EU Stage V.

“Kubota’s ever-growing portfolio of technically-advanced products brings outstanding benefits to both operators and also to the environment. Our new range of micro-hybrid engines is a perfect example of Kubota’s commitment to achieving carbon neutrality whilst, at the same time, helping the machine operators to benefit from both reduced maintenance demands and fuel consumption and enhanced installation ease and machine design flexibility. The overall machine performance is maintained whilst our engines’ efficiency offers reduced cost of ownership through downsizing.”

said Daniel Grant, Manager, Marketing Intelligence for Kubota Business Unit Engines Europe.

The post Kubota Engine Highlights Hybrid and Hydrogen Technologies at CONEXPO appeared first on USA HeavyQuip Journal.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.