Liebherr can boast substantial experience in the development and production of attachments. As far back as 1954, the company designed the first backhoe bucket for its first hydraulic wheeled excavator. Since then, and initially for its own use, Liebherr has continually developed tools for both earthmoving and material handling applications. The result is a comprehensive portfolio that Liebherr has also been offering for corresponding machine types from other manufacturers since 2012. This gives customers a high degree of flexibility in their day-to-day work.

The choice of the appropriate tool has a significant impact on the success of a project. This is why Liebherr has developed such a wide range with each example optimally adapted in terms of shape, properties and technical equipment to the specific application and machine size. Findings gained from practice and continuous product management ensure that Liebherr tools are always state of the art. At the same time, Liebherr ensures that new developments are compatible with the existing product range so that retrofitting or replacement of individual modules is always possible.

Attachments for earthmoving

There are Liebherr attachments for a diverse range of earthmoving applications that can tackle challenges including hard rock, fine sand or bulky demolition material. Liebherr offers numerous options for road construction, civil engineering and tunnel construction, water management, gardening and landscaping, demolition and the mining industry. In addition to backhoe buckets, tilt buckets and trench clearing buckets, tilt rotators, grabs, load hooks and pallet forks are also available. The substantial product range has a modular design. Customers always have access to all relevant optional equipment in every available width of the attachment. This gives rise to countless variants for the common grabs or buckets, which can be configured to meet customer-specific requirements.

Portfolio for material handling

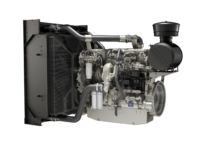

Liebherr offers innovative attachments for material handlers for applications ranging from scrap, timber and port handling through to waste management and recycling. These are customised to meet the specific requirements of the different applications and therefore optimise handling capacity. In the development and manufacture of its attachments, Liebherr always focuses on reliability, productivity and efficiency. Thanks to Liebherr’s flexible and practice-orientated advice, every customer finds the best solution from the portfolio of different clamshell buckets and multi-tine grabs, timber and sorter grabs and various lifting magnets.

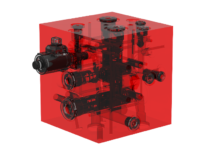

Patented quick coupler system

For increased productivity, efficiency and safety on the construction site, Liebherr offers different levels of configuration for its quick coupler systems to suit specific applications. This way, machines, quick coupler system and attachment always form a high-performance unit for maximum efficiency and economy.

Liebherr’s mechanical quick coupler is the perfect solution when the aim is to increase machine flexibility and productivity whilst minimising investment costs. With the hydraulic Liebherr quick coupler system, a simple and safe change of mechanical tool attachments is possible from the cab. If the patented hydraulic coupling system LIKUFIX® is added, then the quick and safe changeover of hydraulic tool attachments can happen at the touch of a button. With LIKUFIX®, the hydraulic excavator’s range of uses and machine productivity can be increased by up to 30 per cent. All current official standards, as well as the forthcoming IS0 13031 standard, are met thanks to the hydraulic quick coupler’s specially developed safety features.

Future-focused developments

In order to continue to satisfy its customers with excellent results in terms of performance and productivity, Liebherr is constantly developing new solutions for its attachments and quick coupler systems. The continued advance of digital technologies offers various possibilities in this respect. The interfaces and electrical connections between the machine and the attachment are also forward-looking. They make the control of different hydraulic functions, such as transferring GPS receiver signals at the attachment, possible.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.