Bosch Rexroth at bauma 2022: the Booth Tour

At bauma 2022, Bosch Rexroth has presented an integrated portfolio for the needs-based automation of off-highway machines. The range comprehends assistance functions for excavators, wheeled loaders and telehandlers including advanced sensor systems and intuitive operating devices. These include driver assistance functions for more efficient working and even virtual walls and emergency braking assistants for greater work safety. Ready-to-use software modules help to reduce the integration time into existing and future vehicle architechtures and speed up their market launch. As a hardware platform for higher automation levels, Bosch Rexroth will announce a microprocessor-based, ROS2-compatible robotic control unit.

The future of construction, handling and municipal vehicles includes anything from high-performance assistance functions to fully autonomous operation. However, the complexity involved means that manufacturers of off-highway machines are faced with significant challenges. It is important to minimize not only the development outlay but also the technological, economic and legal risks.

The automation portfolio presented at bauma will be based on the proven BODAS kit for hardware, software and telematics. A good starting point are the BODAS AS software modules, in particular the ready-to-use ASRun modules for Rexroth control units (RC), which are easy to integrate. They can be adapted through parameterization and put into operation over the air (OTA).

Functions for greater productivity and safety

The current range of assistance functions for productive and safe working processes includes easier leveling, load capacity measurement during handling operations, electronic vibration damping and various motion control systems for wheeled loaders and telehandlers. Virtual walls and virtual rotary limiting systems protect the immediate surroundings by preventing the machine from accidentally leaving the safe working area. A number of functions can be adapted for other sectors, for example for tractor front loaders.

A groundbreaking HMI concept provides an intuitive user experience. It is based on ergonomic Sense+ joysticks with multidimensional optical and haptic feedback as well as high-resolution, high-contrast and glove-operable BODAS displays with easy-to-record visualizations for the relevant assistance functions.

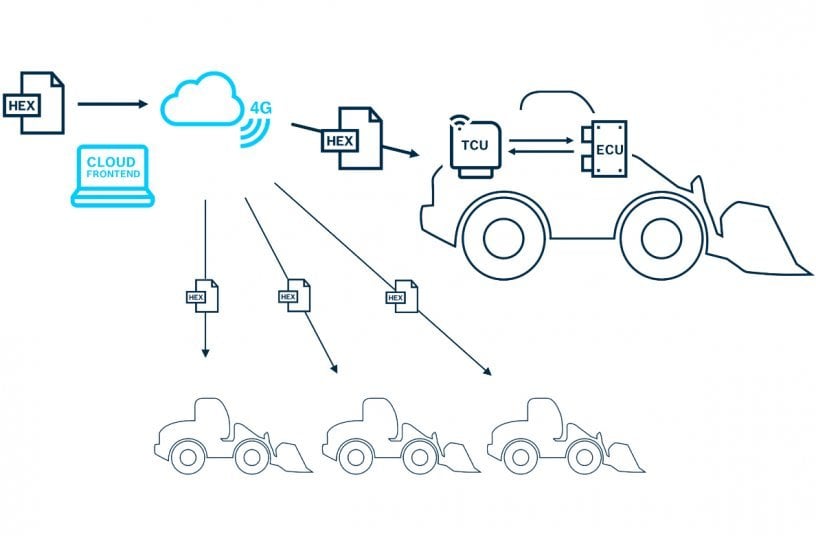

The BODAS ecosystem also includes telematic modules for remote updates over the air (OTA), software remote maintenance and interfaces for transferring the wide range of operating data generated by the automation functions to ERP systems and their digital processes.

The HMI concept also presented for intuitive use of assistance functions and partially automated processes includes ergonomic Sense+ joysticks with optical and haptic feedback as well as high-resolution, high-contrast and glove-operated BODAS displays with easy-to-record visualizations. One application example is the haptic collision protection system nominated for the bauma innovation award.

Within the BODAS Connect Ecosystem for telematics applications, Bosch Rexroth is introducing a range of over-the-air (OTA) services. For seamless machine availability, Rexroth control units and, in the future, also controllers from third-party manufacturers can be remotely updated on a mass scale. Bosch Rexroth is thus making a significant contribution to time and cost savings in the development of increasingly software-based vehicles with partially automated and autonomous functions. The Rexroth Connectivity Unit RCU acts as a secure link between the cloud and the vehicle. The processorbased telematics unit also forms the connectivity basis for a large-scale production-proven device management module and the end-to-end solution BODAS Connect All-in-One Connectivity including data management.

Advancing off-highway automation calls for mass-market remote updates: The new campaign management of BODAS Connect implements this immediately.

Free access to the entire standard BODAS

Whether it’s hydraulic control, automation, connectivity or electrification, software plays a key role in the dynamic off-highway vehicle market. That’s why Bosch Rexroth offers free access to the entire standard BODAS software portfolio for mobile machine control. Through the MyBodas digital platform, OEMs can download validated software packages free of charge to test and adapt them to their needs.

The open ecosystem is continuously growing with standardized and widely documented modules. MyBodas thus offers an always-up-to-date toolkit for various control tasks involving mobile machines. The growing need for automation solutions and the rapidly increasing number of service functions, such as payload estimation, position sensing or surround detection, make this system a very attractive proposition.

Manufacturers of off-highway vehicles now have free access to the complete standard portfolio of BODAS software for controlling mobile working machinery. Via the digital myBODAS platform, OEMs can download validated software packages for a wide range of applications free of charge in order to test them and adapt them to their own needs. Proven building blocks minimize time, investment risks and costs.

Only when the software is used in series production is billing based on a payment model with credits. This makes processing simple, flexible and transparent.

The new sensor systems for ultrasound, radar and inertial measuring systems form the basis for numerous other automation functions by recognizing objects in the surroundings and recording the position of the kinematic systems with respect to each other via acceleration. There are plans to add extra functions and sensors such as Lidar on a step-by-step basis.

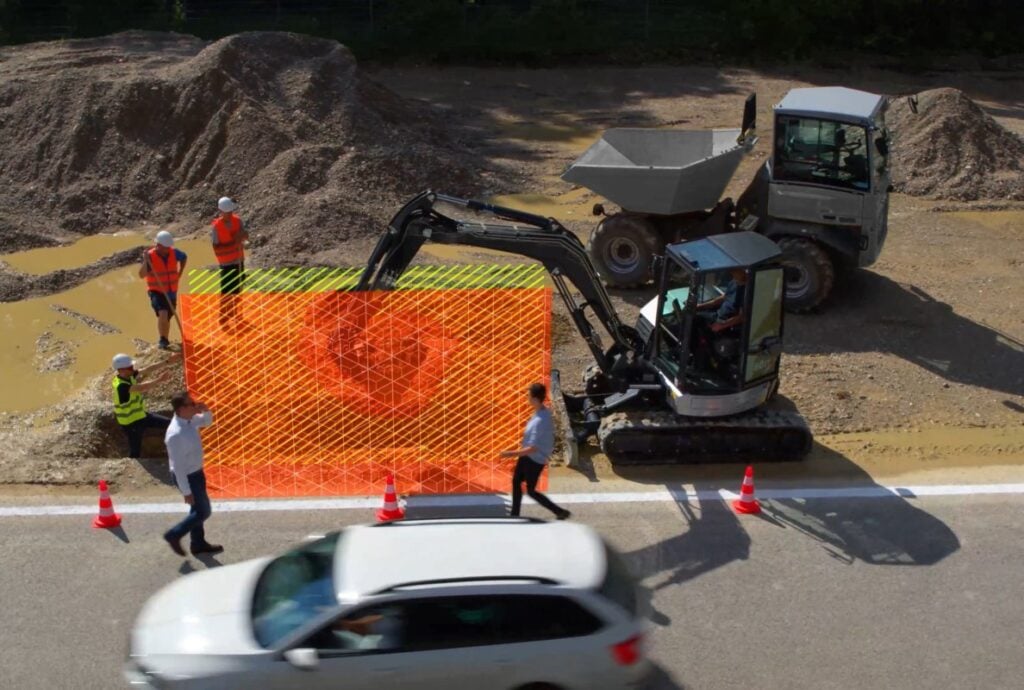

Safety Innovation: The Bosch Haptic Collision Avoidance System

Bosch’s haptic collision avoidance system warns against collisions with intuitive joystick vibrations

Bosch’s haptic collision avoidance system warns against collisions with intuitive joystick vibrations

Haptic feedback increases safety for operators, machines and the surroundings, and the system features automated emergency braking for driving applications.

Using ultrasound for surround sensing, the assistance function warns operators of excavators, wheeled loaders and other construction machinery about imminent collisions, via vibrations on the joystick. Along with the software, these include the USS ultrasound sensors with an intelligent evaluation unit, Sense+ joysticks, DI4 displays and an RC controllers.

The type and intensity of the haptic feedback provide information regarding the distance to the object. If the machine is operated with two joysticks, the system can also indicate the direction from which the object is approaching on the basis of which joystick is vibrating.

The warning reaches the driver’s hands even in noisy environments and without looking at the display.Bosch says this aids reaction time and allows the operator to maintain attention, processes made harder with purely visual or acoustic feedback, an increasingly important consideration in modern modular assistance systems.

For higher automation levels, there is also the option of automatic braking via the electro-hydraulically controlled GEMINI power brake valve from Bosch Rexroth. If the warning is not reacted to in good time, the necessary brake pressure builds up automatically.

For extra practicality, the vibration signal can be varied in terms of intensity and vibration pattern. This allows the distance to a source of danger to be estimated when approaching slowly. If the system is operated with two joysticks, it can indicate the whereabouts of the object on the basis of different vibrations. In combination with visualization on the BODAS display, the exact position can be determined.

The next generation of control units

With the concept of a processor-based robotic control unit, Bosch Rexroth gives an insight into the next generation of control hardware. In the future, it will serve as a standardized, high-performance control platform for higher levels of automation.

The need for high-performance, flexible control platforms is the result of the high computing power required for more automation. And in the future, the ability to develop, port and update software modules quickly and easily will become even more important. With a software architecture arranged in layers, the next generation of control units ensures that this is possible. They are based on Linux as the operating system and a clearly abstracted middleware layer and are compatible with the robotic operating system ROS2.

For object recognition and terrain mapping, Bosch Rexroth is working with Bosch to develop a ROS2-compatible perception stack. On this basis, Bosch Rexroth plans to offer complete function packages in the future – from sensor integration and object recognition to machine intervention. The new control platform is currently being developed. Prototypes for pilot projects will be available from the middle of 2023.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.