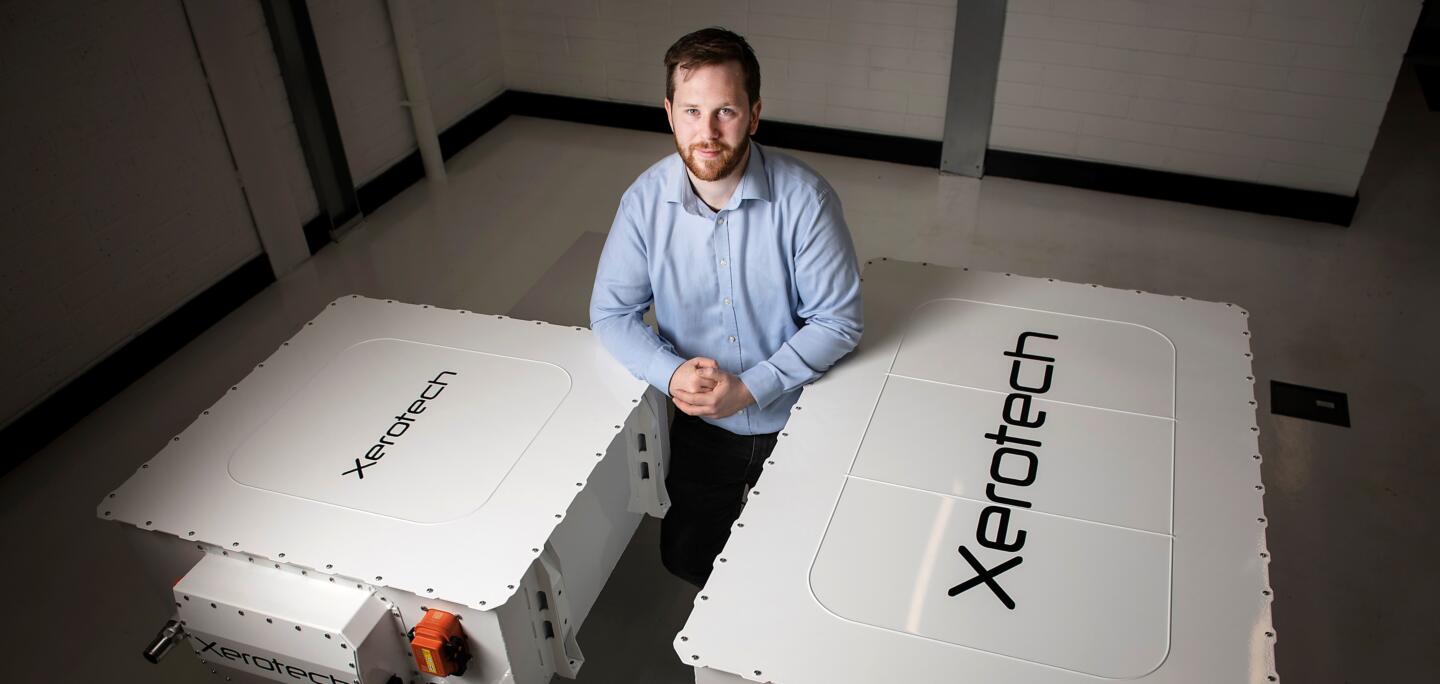

Xerotech was founded in 2015 in Galway, Ireland. The company has been rapidly growing with their new design centre finishing construction at the end of 2020 and future expansions planned. Xerotech provide electrification solutions to off-road industries such as construction, agriculture and mining (CAM). Their modular and scalable battery solution has several benefits which are very advantageous to these markets.

Barry Flannery is the founder and CEO/CTO of Xerotech, a battery technology company that designs, engineers, and produces lithium ion battery packs for non-road mobile machinery. He founded Xerotech in 2015 while completing his PhD, to enable the electrification of the off-highway market which he believes is the next frontier of electrification and will dominate this decade.

***

Can you tell how you started founding Xerotech and what has inspired you to design a modular battery?

When I founded Xerotech the electrification of automotive was well underway and the path was clear. Elon Musk had invented the modern electric car with the Tesla Model S and the launch of the Tesla Model 3 made it clear how the entire automotive industry would shift to battery electric vehicles.

What was unclear at the time was how everything else would electrify? How would construction, mining and agricultural equipment become zero-emission? Automotive is high-volume low-diversity whereas the off-highway heavy-duty segment is low-volume high-diversity. This means that the engineering approaches used in automotive are not scalable into the latter market and fundamentally cannot work.

It is not economically viable to spend millions (or even billions) on EV platforms when the total annual volume is likely to only be a few hundred or thousand machines.

The off-highway market needed a highly scalable and, critically, a highly flexible battery solution that could be adapted to hundreds of different machine types and classes.

This is what Xerotech was set up to solve. It took several years of intense development but eventually we invented our Hibernium™ scalable battery platform with market leading Xerotherm® thermal management and safety technology. The reception and demand from OEMs has been unprecedented which is a tremendous validation of our core assumptions.

Can you explain what is Xerotech’s core business? Can you describe the Xerotech key offering to the heavy-duty manufacturing industry?

Xerotech is a leading manufacturer of advanced battery systems for low-volume high-diversity markets like off-highway and heavy-duty segments. We are a Tier 1 battery supplier to OEMs who manufacture (or retrofit) heavy-duty equipment and we have massively disrupted the market recently with our highly scalable modular battery platform called Hibernium™. Our Hibernium™ batteries can be scaled from 10-300 kWh and up to MWh scale all from a common set of tooling and with no design and development costs.

Xerotech are providing the first truly credible path to zero emissions and we are enabling the electrification of machines that were previously too low volume to be economically electrified.

Your business is based in EIRE: in which markets are you expanding actually?

We follow where the market is growing most rapidly and OEMs for heavy-duty equipment are located worldwide.

However, we see very strong growth in Europe – particularly in the Scandinavian countries as well as North America, particularly in Canada.

Underground mining is currently undergoing a very significant shift to fully electric machines and Xerotech is playing a very active role in this space.

Let’s talk about your modular battery system, the Hibernium: How it could be suitable for all the sector (mining, construction and farming equipment). What is the secret?

There is no real difference between mining, construction and farming battery systems. It is exactly the same as a diesel engine driveline. These are standard off-the-shelf diesel engines that deliver energy/power to the vehicle. The major advantage for Xerotech’s Hibernium™ platform is its high scalability.

We are able to offer a huge range of different sizes and capacities from a common set of tooling and building blocks even below the module level.

This enables the customer to choose a battery system from 10-300 kWh with options in ~5 kWh increments. Crucially, OEMs can leverage the entire manufacturing volume and production process of the full Hibernium™ platform. Whilst a customer may only need a handful of batteries; they are built from subcomponents being used in all of our battery stems meaning that no single customer bears the full burden of tooling and development costs.

A key advantage of Hibernium™ is its market leading thermal management and safety technology. This enables us to operate in virtually any environment and use the battery systems in the heaviest charge and discharge profiles. Our passive propagation resistant design makes the overall solution extremely safe even when using the most energy dense and modern battery chemistries. By standardizing on the 2170 cylindrical cell we are able to offer a huge range of chemistry options to the customer from a diverse base of high quality suppliers.

By combining each of these features together it results in a really compelling technical solution that has generated tremendous interest from the world’s leading equipment OEMs.

According to your experience, which sector has the most positive response to the mobility shift?

Underground mining – no question.

There is an intense market pull right now for electric equipment which is being largely driven by the mine operators mandating fully electric equipment for new mine developments.

We have a unique perspective of the market at Xerotech as we receive RFQs from all the OEMs for their next-generation machines. We can tell you with certainty that there is not a single equipment OEM in the world today who does not have an active electrification program. It is one of the most exciting times in the mining industry since the invention of the steam engine.

There is so much incredible innovation coming and new concepts for machines that were simply not possible with diesel engine architectures.

The automotive market is moving toward electrification very fast. After years of work and experience, what do you think is the biggest difference between the automotive and the offroad vehicle industry going electric?

Automotive is a high-volume low-diversity market whereas off-highway heavy duty is low-volume high-diversity. The engineering requirements for building a battery for an electric car versus heavy-duty equipment are similar in some ways but dramatically different in others.

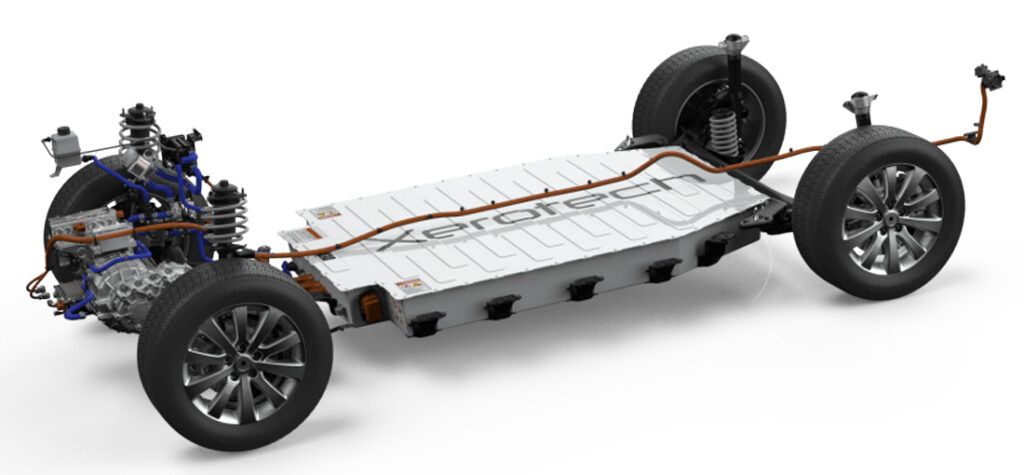

Automotive design is focused on hyper-optimized “skateboard” type battery configurations. An automotive battery “platform” may consist of 2-3 different capacity sizes in the 60-120 kWh range. The design objective is to minimize cost and variation and design entire vehicles on top of a common skateboard chassis.

Off-highway cannot be solved using this approach – it requires flexibility and scalability instead which could be hundreds of different capacity requirements depending on equipment size.

Furthermore, skateboard type designs are fundamentally unsuitable because most equipment uses large diesel engines which are generally big square blocks. This is what Hibernium™ has been engineered to fit; the space left by a diesel engine and transmission unit.

In your opinion, what are electrical energy main problems that need improvement?

The key challenge today is the poor availability of battery systems. Until the launch of Hibernium™ it was very difficult to find a battery system would meet the size, capacity and diversity requirements of mining vehicles.

In general, it is very difficult to source electrification components in low-volumes. Typically, Tier-1 automotive suppliers will not engage in discussions for annual quantities below 5 or 10 thousand units per year. This is an order of magnitude above the annual production of even some of the largest mining equipment manufacturers. Moving forward, it is expected that new suppliers and distribution partners will make these components available to the lower volume segments, but it is crucial that OEMs align themselves with automotive design standards and technology architectures to ensure compatibility.

On the other side, from a diesel operator perspective, why should be a shift on battery system-based vehicles?

The incentive to electrify differs from market to market.

For example, in underground mining, there is a tremendous incentive to eliminate costs associated with the mine ventilation system which can account for 10-20% of mine OPEX.

Mine operators are mandating that new equipment is fully electric so that they can avoid ventilation system CAPEX in the first place and this is creating a tremendous demand for fully electric equipment.

Furthermore, eliminating harmful emissions massively improves air quality in the mine and improves the working environment for miners and equipment operators.

Electric machines are cheaper to operate, more reliable, more powerful and are not restricted by diesel engine emission limits. Battery systems can deliver very high peak power which is very helpful in loading applications and others with transient work profiles.

Construction equipment can also benefit from clean and quiet operation which is especially important in modern urban construction environments subject to low and no emission zones.

Why manufactures should prefer Xerotech as a supplier?

Xerotech is the first battery system supplier to bring automotive-grade battery systems to the off-highway market.

Our technology matches and in some cases surpasses the current state-of-the-art in modern electric vehicles. Xerotech are offering one of the best tailor-made battery solutions to mining equipment OEMs at competitive prices and are willing to work with all manufacturers regardless of annual unit requirements.

Xerotech is on track to become a major Tier-1 supplier of battery systems in the future and it is a fantastic opportunity for OEMs to secure strategic partnerships today to secure the future of their businesses.

Also, on Linkedin, I saw that you are hiring. What kind of profiles are you searching for and from where?

That’s right! We are currently undergoing extremely aggressive expansion and our current headcount stands at over 40 people and we have new faces joining each week. We will have around 90 people onsite by the end of this year. Some of the areas that we are hiring heavily in are embedded software systems, battery system engineering, high-volume automotive quality, high-volume manufacturing engineering.

We are hiring from all around the world and competing head-to-head with the world’s leading EV startups and OEMs for talent. We currently have over 15 nationalities working at Xerotech.

At Xerotech, attitude is the single most important characteristic for new hires. We take a similar approach to Tesla and SpaceX with regard to our engineering talent – it is usually the best in the world and everyone who works here believe in our mission and that they are part of something bigger.

Eventually, what Xerotech is planning for the next year?

The next 12-months will be the most exciting and transformative in Xerotech’s history.

We are currently raising $30m to fund our fully automated serial-production line which will come online in Q1 2022. By the end of the 2022 we will have a full-rate production capacity of around 500 MWh of battery systems which would be sufficient for around 7,500 machines per year.

Xerotech is on track to become a very dominant player in this market segment over the next few years and we are very humbled to be able to contribute to the electrification of such an important part of industry.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.