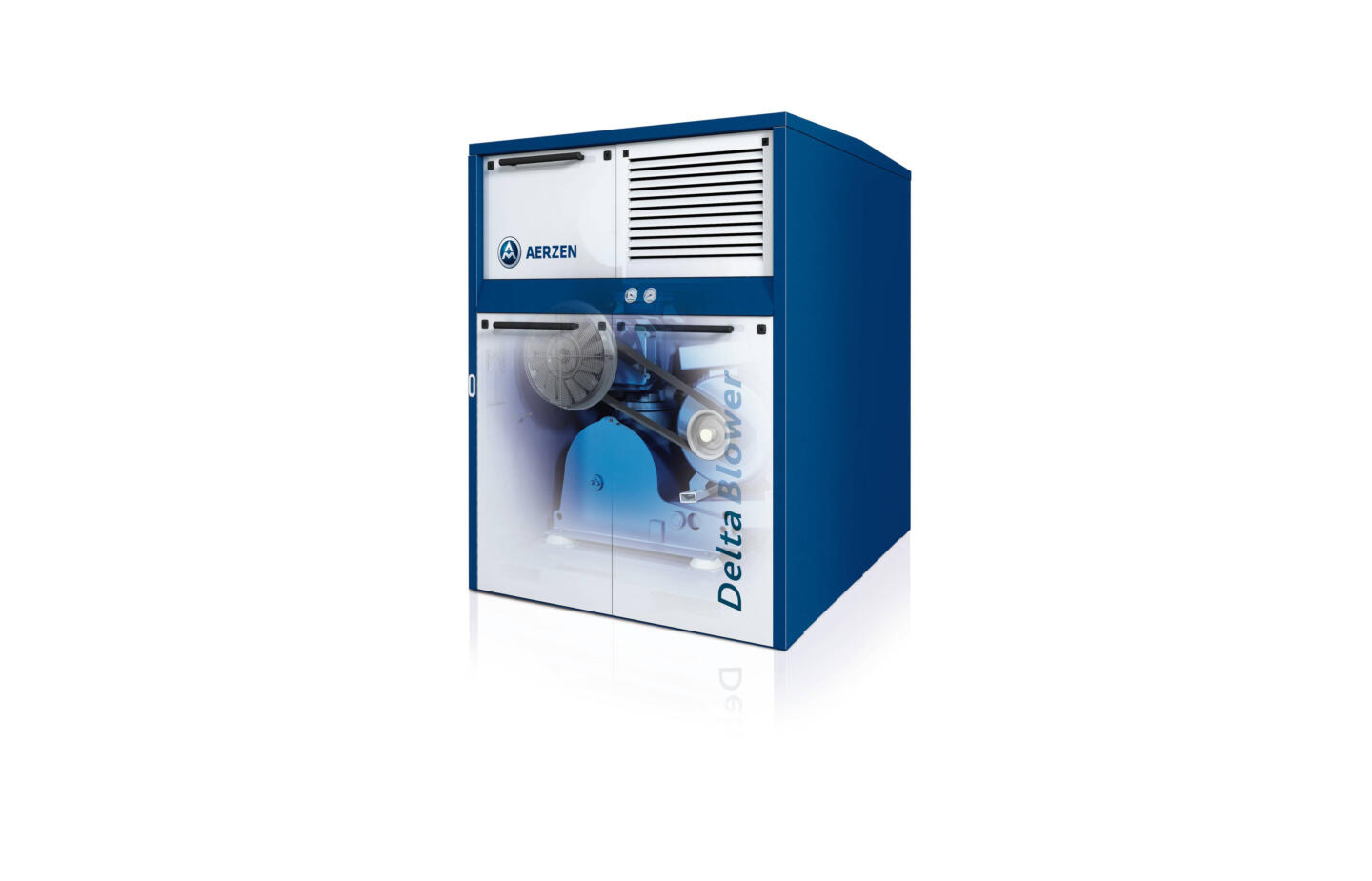

The Delta Blower Generation 5 is the 5th generation of Aerzen blower units and represents the successful combination of tradition and innovation. These blowers act as the driving force behind many processes and are the beating heart of a strong machine combination.

The roots design paved the way for the development of Aerzen’s positive displacement blowers: even now, 150 years later, it remains one of our most successful products. Today Aerzen’s twin-shaft positive displacement blowers for oil-free conveyance show greater innovation. The many developments in construction ensure top ratings when it comes to efficiency.

One unique aspect of the Delta Blower stages Aerzen has developed is the pulsation reduction chamber. The patented Aerzen process prevents pulsations and noise already at the origin within the blower stage. The Aerzen blowers equipped with 3-lobe pistons have two special channels cast in the cylinder. These control the backflow of the medium into the conveying chamber in such a way that the typical backstroke and squeezing pulses (typical for 2-lobe blowers) are eliminated.

This blower class remains robust, reliable, and has a long service life.

The versatile and compact Delta Blower units can be deployed in any climate zone on Earth. In the most challenging outdoor environments just as safely as in covered indoor spaces. They can be used as both standalone units and in complex assemblies. They are as reliable in earthquake zones as they are aboard ships or in other mobile applications.

Operation-Friendly, Low-Maintenance Design

- Control and maintenance from the front of the machine

- Oil levels can be checked with the machine running and are readable from outside the machine

- Plug & Play (Pre-configured, parameterized, ready to run)

A plus for the environment

- Energy-efficient Class IE3 motors as standard equipment

- Newly developed E-Design for even more energy efficiency

- The increased efficiency class on IE4 motor improves the energy saving on the blower assemblies and therefore the whole life cycle cost.

Low noise levels

- For easy compliance with noise level regulations near populated areas and production facilities

- Minimal noise levels with optimized acoustic hood

- Integrated pulsation reduction process (patented AERZEN blower stage)

Technical data

| Type of technology | Positive displacement blowers |

| Design | Positive pressure, negative pressure |

| Volume flow | 30 to 15,000 m3/h |

| Medium | air, neutral, gases |

| Conveying | Oil-Free |

| Negative pressure | -500 mbar |

| Positive pressure | 1,000 mbar |

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.