Solid-state technology is emerging as a disruptive force in the electrification of vehicles and industrial machinery.

Aliant Battery, a brand of lithium batteries by Elsa Solutions, has announced the launch of its solid-state lithium battery. This technology is set to transform energy storage solutions, especially for heavy-duty applications.

While some car manufacturers anticipate integrating this technology by 2026/27, no major carmaker is currently producing solid-state cells. The advancements offered by solid-state cells include significant improvements in both volumetric and gravimetric energy density, as well as enhanced safety features.

Addressing Thermal Runaway and Its Hazards

Thermal runaway is a phenomenon where a battery heats uncontrollably due to internal reactions, often triggered by overloading or physical damage. This can lead to catastrophic events like fires or explosions, especially in confined spaces with limited ventilation, fluctuating temperatures, and high-demand scenarios. Despite technological advancements, Li-ion batteries remain susceptible to this issue. However, solid-state lithium batteries offer a safer alternative due to their unique composition and design, making them immune to thermal runaway. This critical safety advantage makes them ideal for high-risk applications.

The Aliant Battery Solid-State Lithium Solution

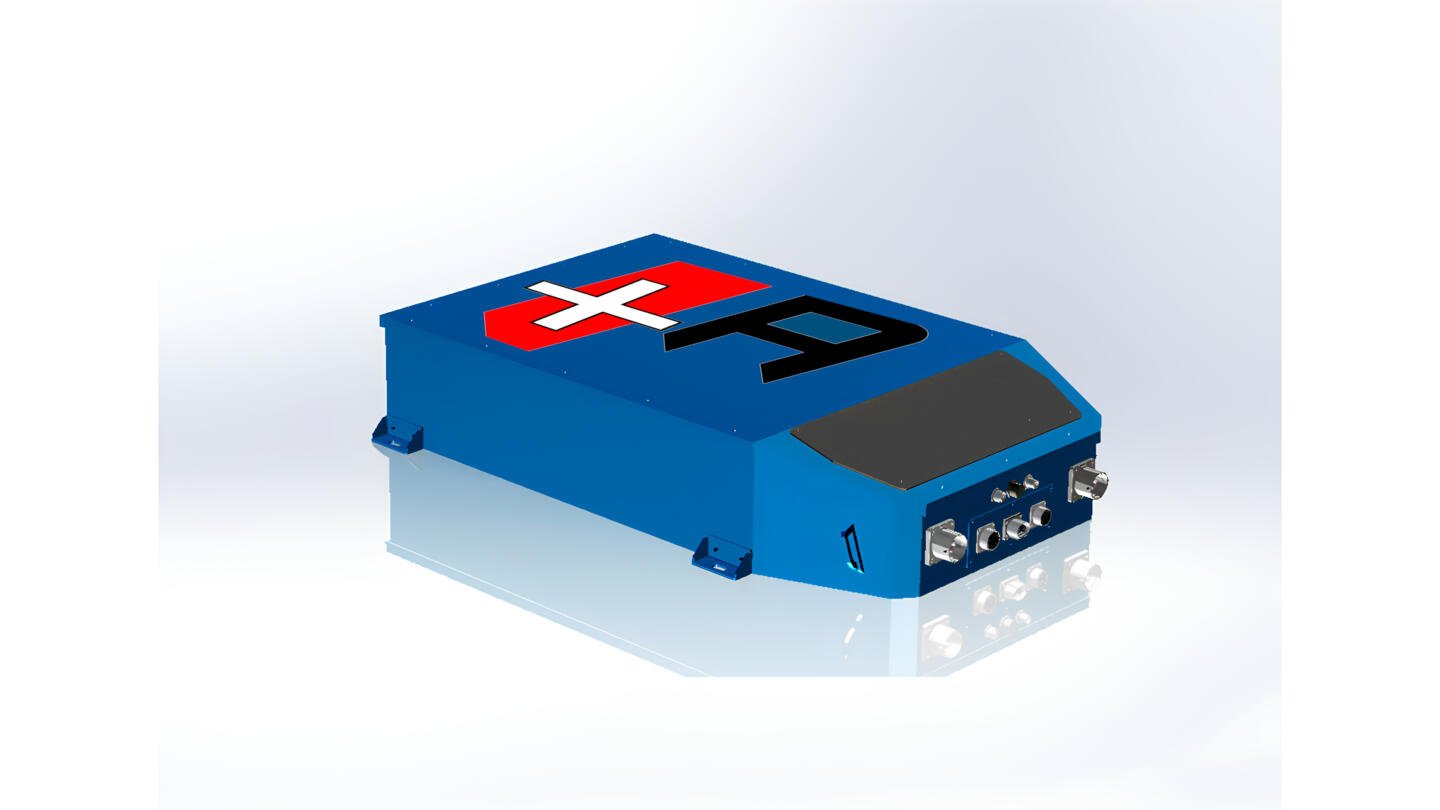

The Aliant Battery solid-state lithium battery, referred to as the SSC Battery, features a scalable module of 56V / 246Ah / approximately 14Kwh. Engineered with innovative technology, these batteries ensure maximum robustness and safety, setting a new standard for high-power stationary energy storage and marine applications. Encased in an automotive-derived aluminum shell, they achieve energy density levels of approximately 220 Wh/kg and around 250 Wh/l at the battery pack level. Aliant Battery’s proprietary Battery Management System, Pegasus BMS, and multiple quality checks at every production stage highlight the Italian brand’s high standards. Specifically designed for special propulsion systems, these batteries support full electric and hybrid propulsion, offering maximum efficiency and a high protection level (IP65).

“As a manufacturer of LiFePo4 batteries, we understand the critical importance of guaranteeing dedicated safety and reliability standards for every environment, including the most critical ones. This is particularly true when it comes to mitigating the risks associated with thermal runaway.”

said Riccardo Massaro, Aliant Battery export sales engineer.

Maximum Safety and Remote Diagnostics

“Safety is one of our top priorities, which is why our solid-state lithium batteries incorporate advanced safety features such as gas expulsion mechanisms, deep discharge protection, and proprietary algorithms for state-of-charge and state-of-health determination. Additionally, our batteries facilitate on-site and remote diagnostics and monitoring through our diagnostic software and optional Athena Web Portal connectivity, ensuring proactive alerts and comprehensive oversight.”

explained Massaro.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.