Booth A4.338

At Bauma, Cummins will showcase its Next-Gen X15 engine for Off-Highway applications, a scaled model of the QSK60 for Mining, and the Meritor MOX E8 telehandler axle. The company will also showcase PrevenTech, its telematics-based connectivity solution.

“We’re making record investments in our technologies and have one of the broadest portfolios of power solutions for industrial applications in the world. Our versatility, scale and longevity position us to help OEMs succeed and we’re thrilled for the opportunity to meet with many of them this year in April at the Bauma trade fair.”

said Marina Savelli, Vice President, Off-Highway at Cummins.

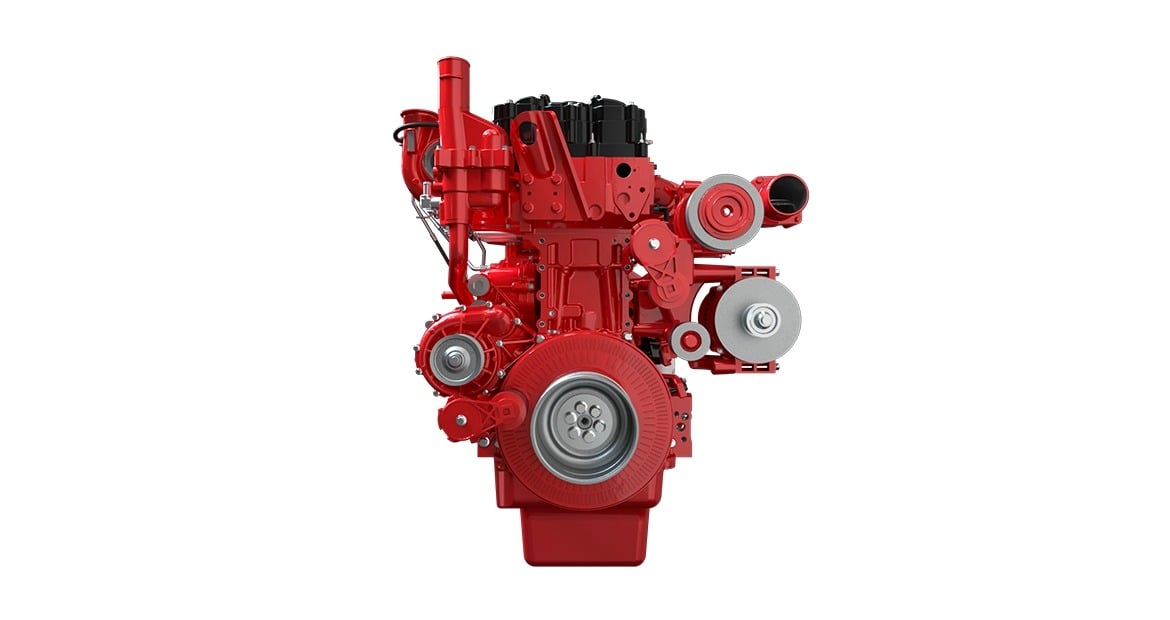

The X15 powers applications such as large construction bulldozers, cranes and excavators, and is part of the Cummins HELM fuel-agnostic engine platform. The platform’s new power solutions can utilize clean diesel, natural gas, renewable biofuels, or hydrogen, ensuring compatibility with evolving environmental regulations while supporting unique customer requirements during the energy transition. The X15 will offer digital connectivity features, improved fuel economy and longer service intervals compared to its predecessor; all in a smaller package size similar to a 13L engine. Ratings for the X15 will be up to 522 kW (700 hp) and a peak torque of 3200 Nm (2360 lb.-ft.), targeted for Stage V emissions and beyond.

Also on display will be the Tier 4 Final/Stage V compliant Cummins QSK60, which delivers a maximum of 2125kW (2850hp) and a maximum torque of 11,218Nm (8274 lb.-ft.). Equipped with an advanced diagnostics solution, PrevenTech, and serviced by Cummins’ global distribution network, the QSK60 provides over 40,000 hours of operation before requiring an engine overhaul. This engine can then be rebuilt over three times throughout its lifetime, significantly reducing the potential total cost of ownership (TCO) for miners. Cummins’ Power Systems business recently expanded on how its bridge technologies will be used to support the mining industry’s energy transition, including the development of two bridge pathways – hybrid and clean fuel capabilities.

The Meritor MOX E8 telehandler axle will be debuting on the Cummins booth at Bauma this year. Used in the most extreme duty cycles and applications around the world, Meritor axles are recognized as an industry leader, and the new MOX telehandler provides OEMs proven technology backed with global, localized distribution, and award-winning customer service—all designed to improve the bottom line and maximize uptime.

Cummins’ Journey to Reduced Emissions

Featured in the Bauma Forum at 5:00pm on April 7, Destination Zero will be the focus of a keynote presentation on the topic of Climate Neutrality. Cummins’ Jonathan White, Vice President, Engine Business Engineering will speak on decarbonization and the journey Cummins is on towards more sustainable solutions—including what Destination Zero means for Off-Highway and Mining applications.

Destination Zero is Cummins’ multi-solution, dual-path approach that leverages advancements in engine-based technologies while progressing zero-emissions solutions as markets adapt, and customer demand grows.

Visitors to the Cummins in hall A4, stand 338 will have the opportunity to see products up close, speak with technical experts, and learn more about Cummins’ comprehensive range of power solutions.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.