Cummins announces its new bridge technology strategy and displays advanced internal combustion products for mining applications at MINExpo 2024. Taking place 24-29 September in Las Vegas, U.S., Cummins discusses the role of bridge technologies, such as hybrid solutions, in reducing mining emissions and Total Cost of Ownership (TCO) for miners. Displayed on stand, Cummins is showcasing its latest generation QSK60 and QSK95 engines.

Hybrid Capabilities

MINExpo will be the occasion to discuss about Cummins hybrid capabilities and its new bridge technology strategy launch for the sector. Cummins highlights its core, modular hybrid architecture alongside plans for both first-fit and retrofit applications for miners. The company believes hybrid solutions offer an affordable way to reduce emissions like trolley assist which can be used in cohesion with HVO-ready internal combustion engines to generate additional emissions benefits.

Advanced ICE

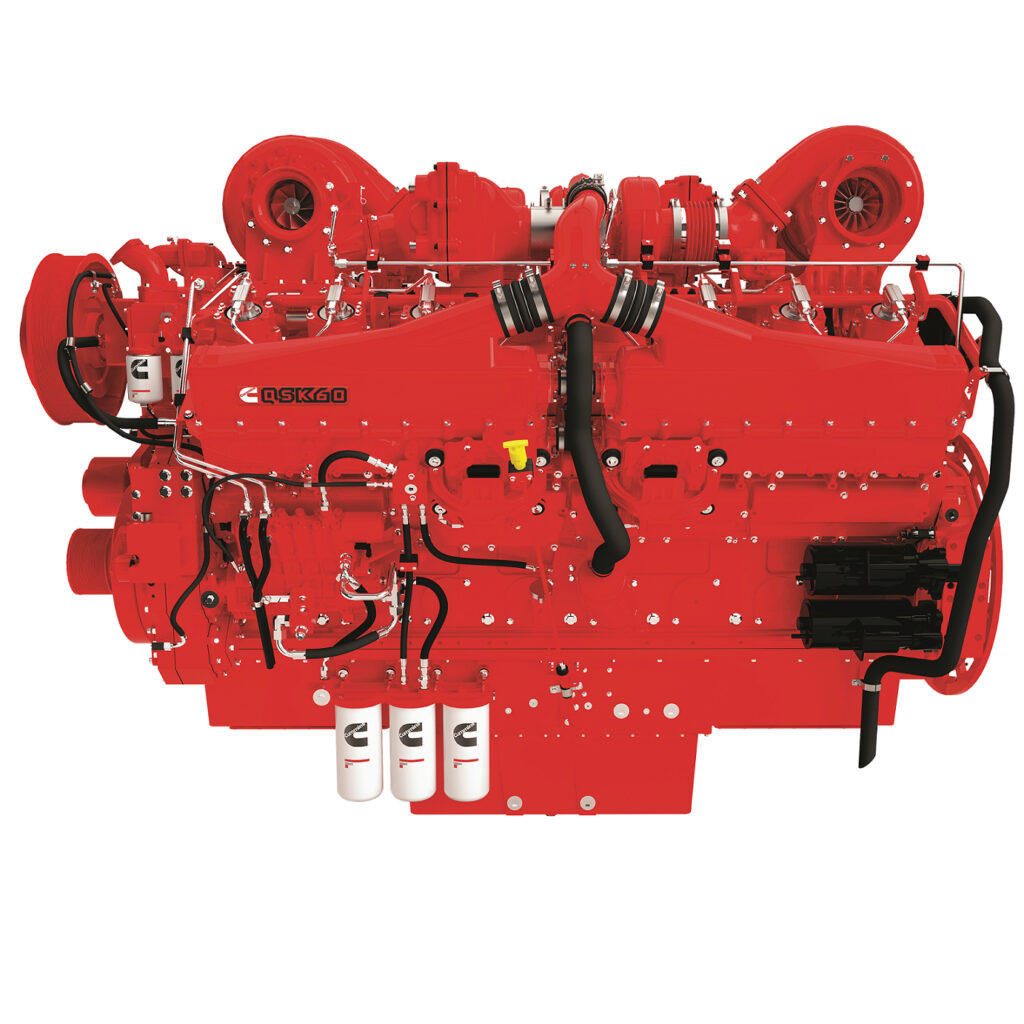

Leading the showcase of internal combustion engine technology is the Tier 4 Final/Stage V compliant Cummins QSK60, which delivers a maximum of 2850hp (2125kW) and a maximum torque of 8274lb-ft (11,218Nm). Equipped with advanced diagnostics and serviced by Cummins global distribution network, the QSK60 provides over 20,000 hours of operation before requiring an engine overhaul.This engine can then be rebuilt over three times throughout its lifetime, significantly reducing the potential total cost of ownership (TCO) for miners.

In addition, Cummins displayes its QSK95 on-stand. This EPA Tier 2 emissions equivalent is the most powerful mining engine available and features an output of over 4400hp (3281kW) and a peak torque of 17802lb-ft (24136Nm). The 16-cylinder QSK95 is a clean sheet engine platform, designed with optimum power-to-weight ratio for 400T haul trucks, with engine ratings to maximize fuel efficiency and productivity. The engine also utilizes four single-stage turbos, alongside external oil and lube coolers, to improve engine serviceability.

PrevenTech

Visitors to the Cummins booth at MINExpo is also see the company’s latest developments in advanced diagnostics and prognostics with PrevenTech. The technology detects potential equipment health issues before they occur, informing operators of potential performance issues and recommended service ahead of failure and subsequent downtime. Cummins PrevenTech is a system that can be installed on Cummins engines to reduce TCO from unexpected servicing for miners.

Cummins Global Support

At MINExpo, Cummins discusses about how choosing its engines leads to low cost of production thanks to its extensive aftermarket service and support.

Cummins engine rebuilds go through a six-stage remanufacturing process that sees the engine disassembled, cleaned, inspected, re-machined, reassembled with Genuine Cummins parts and tested. As a result, the engine’s life is extended, its performance is enhanced and TCO is reduced due to greater engine uptime.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.