At this year’s Kohler Demo Days, held at the company’s plant in Reggio Emilia, Italy, the focus was on the KSD series, in production since 2023. In addition to the KSD series, Kohler also highlighted the KDI 2504 engine.

At the event, representatives of Kohler partners such as JCB, Merlo, Caron, Cormidi, MDB and MultiOne presented and field-tested their machines equipped with Kohler engines in the plant’s Demo area, showcasing their capabilities under various operating conditions.

“Demo Days are more than just an event; they represent our ongoing commitment to supporting customers throughout the entire process of adopting and developing the best solutions for their needs. We are deeply grateful for the trust our customers have shown over the past two years by supporting this initiative, which will become a regular event featuring a variety of customers. Our press partners have been with us on the journey of sharing our history and innovations, and we are proud to continue cultivating this valuable relationship.”

said Nino De Giglio, Director of Marketing Communications & Channel Management at Kohler Engines.

KSD Series

In the Demo area, attendees had the opportunity to see Kohler’s KSD engines in action on JCB, MultiOne, MDB and Caron machines.

The Kohler KSD is a new base engine below 19 kW that complies with all global emissions standards and fuels. The innovative technology brought on by the KSD is its architecture: it features an indirect injection system but has the electronic management typical of direct injection engines. The indirect injection system does not affect the fuel consumption rate: on the contrary, the electronic management and the focus on clean combustion drive low oil and fuel consumption and avoid oil dilution as well as heavy soot oil contamination.

The KSD’s versatility allows for easy-to-integrate solutions that are compatible with all kinds of machines.

The engine platform is designed to increase machine productivity, reduce cost of ownership, and minimize downtime through careful engine mapping and extended maintenance intervals.

“Over the past two years, we have been closely supporting our customers in integrating the new KSD engine into their machines, and the benefits are numerous. In forklifts, we have achieved a 10% fuel savings in a typical duty cycle. For aerial lifting platforms, there is improved load response, and in mini excavators, there is enhanced performance and optimal operation even under extreme conditions. In articulated loaders and their various implement attachments, the engine is able to adapt to all conditions and provides superior responsiveness.”

said Abhiroop Garg, KSD Product Manager.

KDI Series

In addition to the KSD series, Demo Days also highlighted the KDI 2504 engine. With over 350,000 units produced to date, the KDI series has made a significant impact in North America, Europe, and Asia, particularly in the construction and agricultural markets, accumulating a total of 1 billion field operating hours. The KDI series is versatile and excels across a wide range of applications.

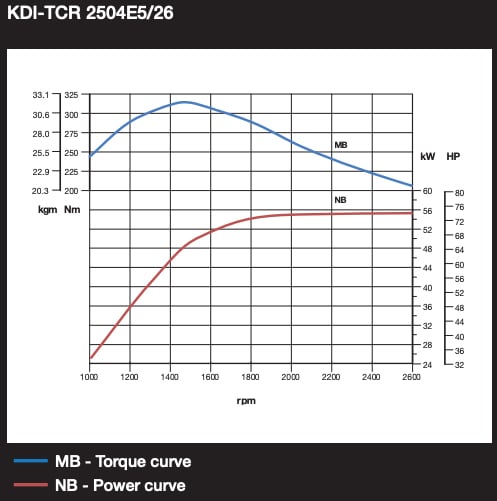

For the KDI series, Kohler has selected the most advanced common rail system available on the market and specifically engineered for extreme durability and longevity within agricultural, industrial and construction equipment applications. The 2000 bar high-pressure pump, together with the advanced multiple injection control of the solenoid injectors, allows excellent fuel rate control during the injection process.

The waste-gated turbocharger has been specifically tuned to minimize the turbo-lag response and provide a precise volume of air for an excellent low-end torque capability. The special design of the lubrication system guarantees extended durability of the turbocharger. The use of a charge air cooler is required to ensure the correct air inlet temperature for optimal engine performance whilst achieving emissions compliance.

The 4 valves per cylinder design has been selected to enable the installation of the injectors precisely on the cylinder axis and centered with the combustion bowl. This solution allows for a symmetrical fuel atomization and distribution within the combustion bowl ensuring optimal mixing of fuel and air. The design of the combustion bowl itself together with the inlet ports shaping have been studied and developed with CFD analysis to complete the absolute optimization of the combustion process.

![[Video] New Generation DAF Trucks in ‘Construction Simulator’ Game](https://www.heavyquipmag.com/wp-content/uploads/2024/12/DAF-trucks-218x150.jpg)

![[Video] How a Huge Mining Excavator Can Be Electric](https://www.heavyquipmag.com/wp-content/uploads/2025/01/liebherr-r9400e-fortescue-218x150.jpg)

![[Job Story] Manitowoc Grove GMK5250XL-1 at Work in Semiconductor Facility in South Korea](https://www.heavyquipmag.com/wp-content/uploads/2025/01/Manitowoc-Grave-218x150.jpg)

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.