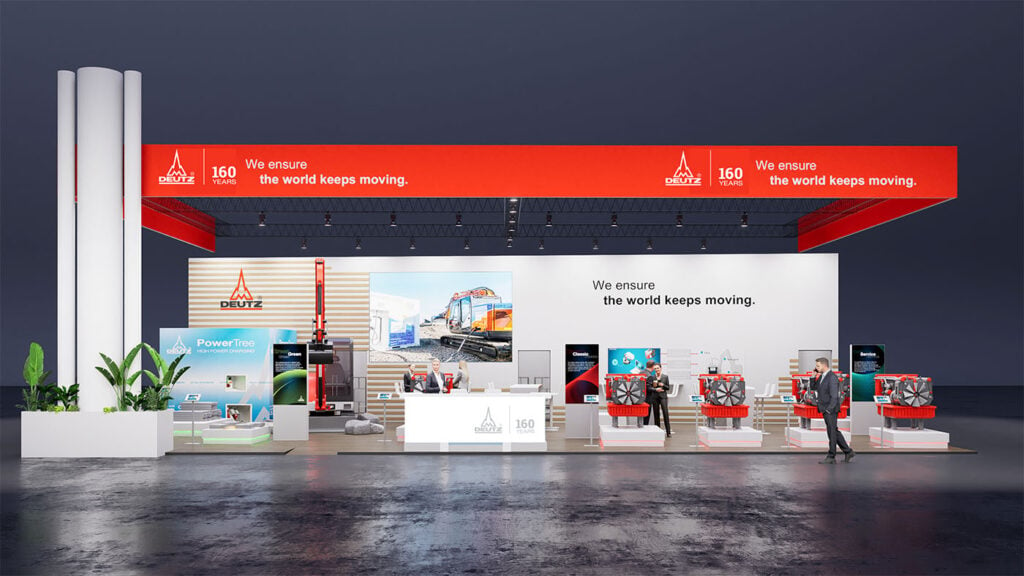

Deutz is showcasing its latest developments in the field of construction and material handling at Intermat. ‘We ensure the world keeps moving’ is the banner under which the company is offering diesel, electric, and hydrogen technologies to create solutions that best meet the needs of its customers. Deutz’s TCD 3.9 engine in the sub-4 liter category, which delivers up to 130 kW, is displayed at Intermat. The engine is available in variants fueled by lower-emission alternatives such as gas and hydrogen.

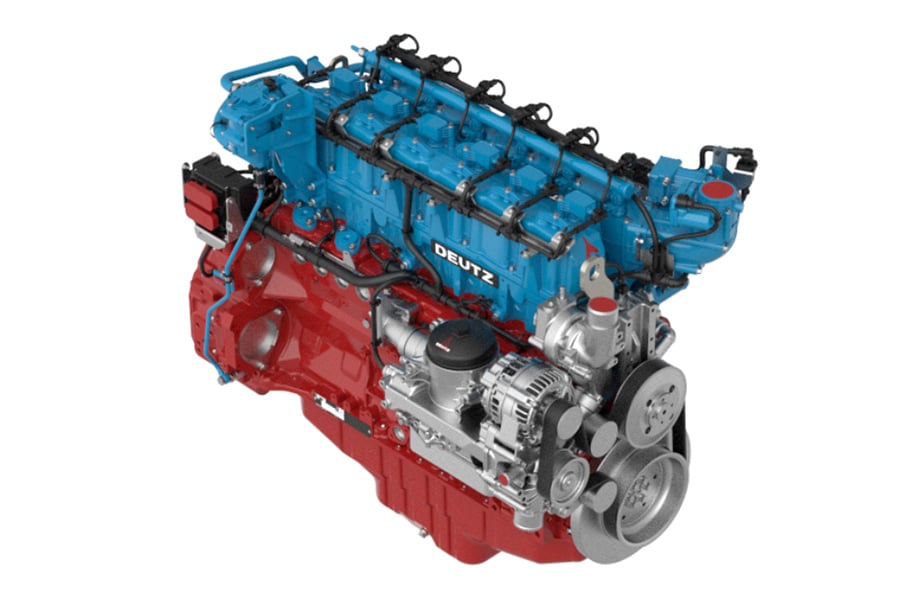

Deutz is giving trade visitors to Intermat an overview of its Classic portfolio – ranging from smaller engines such as the Deutz TCD 2.9 to the high performance T(T)CD 7.7 engine. All engines in the TCD series meet the highest emission standards and are approved for use with HVO biofuel.

Equipment for use on the construction sites of the future are also displayed: an electric excavator, powered by Deutz Electric System, and the Deutz PowerTree mobile rapid charging system. The PowerTree, which can be used independently of the local power infrastructure, provides a charging capacity of up to 150 kW with an output voltage of up to 800 volts, meaning that construction machinery can be charged in just 20 minutes.

“With our various drive systems, we offer different ways to achieve emission-free mobility. E-drives from DEUTZ are already enabling a wide range of zero-emission applications on construction sites – and the PowerTree is the ideal solution where there is a lack of charging infrastructure.”

said Dr. Ing. Markus Müller, member of the Board of Management of DEUTZ AG with responsibility for technology and sales.

Deutz is demonstrating its system expertise with an excavator whose internal

combustion engine has been replaced with the 360-volt drive system (E360) from Deutz. The built-in system with two lithium-ion batteries has a continuous power output of 40 kW and peak power of up to 80 kW. It is the first E360 system that can be charged rapidly using a DC charging connector. The aim is to be able to recharge the battery capacity within 30 minutes (from 20 to 80% state of charge). The retrofitted excavator is being used for testing purposes to see if customer requirements can be met.

Also from its Green segment, Deutz is showing its TCG 7.8 H2 hydrogen combustion engine. The engine is scheduled to go into full production at the end of this year and is suitable for use in all current Deutz applications as well as in the on-highway segment.

Deutz offers an engine reconditioning service. DEUTZ Xchange reconditioned engines and parts provide a fast, cost-efficient, and environmentally friendly alternative to buying new. They are also available for engine series that have been discontinued for some years now.

At Intermat, Deutz is also presenting a cloud-based platform that collects data in real time to make it easier to optimize how machines are used. The direct access to data can be used to prevent the occurrence of faults.

“Our range of services does not stop at simply maintaining our engines. DEUTZ FUSION HUB is an integrated telematics solution that can optimize operations digitally – reducing non-productive periods and saving our customers time and money.”

said Darko Kostic, president of DEUTZ France.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.