At Intermat, Liebherr will showcase around 20 machines from the product segments of tower cranes, mobile and crawler cranes, components, earthmoving machinery, material handling technology, deep foundation machines and concrete technology. Not only the static exhibits of products but also a showcase of the range and innovation work of the Group in the fields of digitalization, drives and service will form the focus of the company’s 3,264 m2 booth at the trade show.

Liebherr Bucket Fill Assist in the R 972 crawler excavator

An R 972 of the generation 6.2 crawler excavator with an operational capability of approximately 72 tonnes will be on display at Intermat. What sets the R 972 apart is its productivity, driving comfort and modern design. The low fuel consumption and the innovative assistance functions make it an ideal machine for the requirements of large-scale construction sites and extraction sites.

The R 972 crawler excavator features the Liebherr assistance system Bucket Fill Assist (BFA). This innovative system, developed by Liebherr, facilitates a better fill level of the bucket, faster cycle times and better penetration of the material. As well as reducing the wear on the bucket, this reduces fuel consumption by up to 10% and reduces vibrations for improved driver comfort.

LRB 23 piling and drilling rig

With its LRB 23 piling and drilling rig, Liebherr will present an all-rounder for deep foundation, with an impressive engine output of 600 kW. This allows the machine to deliver the capacity needed for all common deep foundation applications. Since it can withstand high torques, it is even suitable for Kelly drilling – a unique property for a machine in this size class. The Kelly visualization of the LRB 23 makes locking the telescopic sections of the Kelly bar much simpler. Plus, the concreting process is automated in continuous flight auger drilling thanks to the drilling assistance feature.

TA 230 Litronic articulated dump truck

Liebherr will present the TA 230 Litronic articulated dump truck. The powerful off-terrain machine is designed for operational efficiency in the extraction industry and when transporting excavated material. The articulated dump trucks are also a useful assistant for larger infrastructure projects. Liebherr offers numerous cutting-edge driver assistance systems for the TA 230, which support the machine operator and, in turn, increase productivity and safety. One example of this is the innovative weighing device, installed as standard, which registers the loaded weight in real time.

MK 140-5.1 mobile construction crane

Liebherr will display the MK 140-5.1, the strongest Liebherr mobile construction crane with a load capacity of up to 8,000 kilograms. What makes it special, aside from its regular use as a trolley jib crane, is the VarioJib: this allows for operations in luffing mode and up to 65 meters of jib length. The ecological and future-proof hybrid power concept enables fully electric crane operation using either site power or another external power source. As a result, the crane works particularly quietly. It is compatible with the Liduro Power Port (LPO) from Liebherr, the mobile energy storage system for supplying power to construction sites.

For short operations: 125 K fast-erecting crane

The 125 K fast-erecting crane offers maximum stroke capacity yet takes up only minimal space. It has a variety of hook heights, which means it can be adjusted to the site conditions for extra flexibility. With a jib length of 55 m and a hook height of up to approximately 66 m, the 125 K is currently the largest fast-erecting crane on the market. A meticulously designed assembly system and low logistics costs make the Liebherr cranes a particularly interesting option for shorter projects.

The first electric Liebherr wheel loader, the L 507 E

The Group’s first battery-electric wheel loader L 507 E, which is available in several European countries, will also be on display. It combines the well-known benefits of a Liebherr stereoloader with a Liebherr-developed battery-electric drive concept. The performance of the L 507 E is identical to Liebherr’s conventionally powered wheel loaders in the same size class. With its L 507 E, Liebherr is showing its commitment to a high-voltage battery system developed specifically for wheel loader applications, which ensures highly effective delivery of power and efficient loading operations.

Electric truck mixer: ETM 1205

When combined with an electric chassis, the new ETM truck mixer series featuring an electric drum drive renders it possible to transport concrete without producing emissions. The process of unloading concrete on the site is also clean and quiet. The ETM attachments are available as fixed superstructures and semi-trailers. Visitors will be able to see a fully electric articulated ETM 1205.

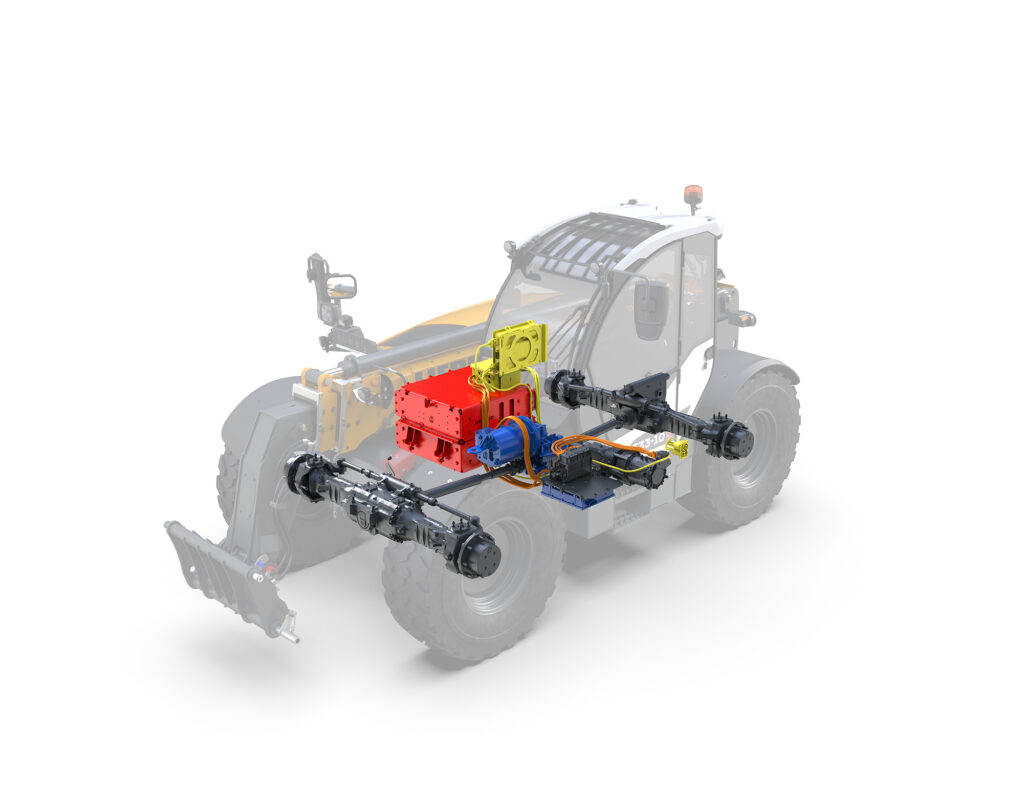

The T 33-10 telescopic handler

The portfolio of international client operations using telescopic handlers and crawler dozers is hugely varied. True to its open-minded attitude to technology, Liebherr will present a battery-electrical operated telescopic handler, the T 33-10. What makes the Liebherr telescopic handler stand apart is its choice of drive concepts that are aligned to the application or the market, as necessary: hydrotreated vegetable oils (HVO) as a low-emission counterpart or additive to fossil fuels, a battery-electric drive; or a hybrid drive consisting of a combustion engine and an electric motor.

The LTR 1150 telescopic crawler crane

With the development of the LTR 1150, Liebherr expands its range of telescopic crawler cranes to include a 150-tonne model. Despite offering roughly 50% more load capacity than the LTR 1100, the new crane is as simple and economical to export as its 100-tonne counterpart: available either complete with crawler frames, at a total weight of 60 tonnes and a transport width of 3.5 meters or without crawler frame, weighing just 38 tonnes in total and measuring just 3.0 meters in width. In a first for telescopic crawler cranes, the LTR 1150 features Liebherr’s VarioBase, which the crane control uses to determine the best possible load capacity depending on the track width and angle of rotation.

The 36 XXT truck-mounted concrete pump

The 36 XXT truck-mounted concrete pump benefits not only from a new five-part folding boom, but also from the Powerbloc drive unit and the semi-closed oil circuit. It is a versatile machine offering numerous comforts and safety features, such as ergonomic steps and simplified access. An ultra-compact design without any boom overhang at the rear makes it extremely manoeuvrable in tight spaces. A particular highlight of the 36 XXT concrete pump is the newly developed ‘Powerbloc’ pump drive unit, which has the major benefit of all hydraulic switching and measuring elements being fully integrated.

Source: Liebherr

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.