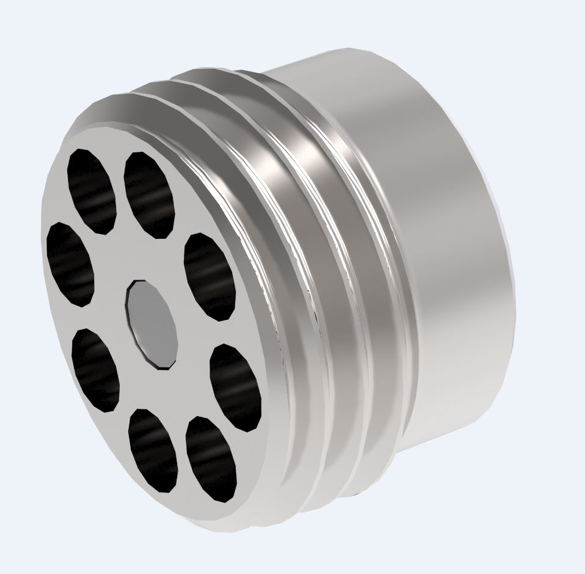

For many years, the RKVG and RKVE ball check valves series have been proving their great usefulness in tough applications in construction and agricultural machinery as well as in industrial applications. Bucher Hydraulics has now added valves in sizes 04 to 16 and thread sizes G1/8″ to G3/4″ in a shortened design to complement its range. The perfect response to shrinking installation spaces in modern machines and systems.

Check valves allow media to flow in only one direction and prevent backflow in the opposite direction – similar to a diode in electrical applications. Over many years, the specialists at Bucher Hydraulics in Dachau have continuously optimized this unobtrusive component, which is often concealed inside hydraulic blocks. It is used in industrial and mobile applications, from excavators to injection molding machines.

Shorter and compatible

The latest example of this development are the new, extremely compact ball check valves from the RKVE-KB and RKVG-KB series (KB = compact design). These valves are between 2 and 3 mm shorter than the standard versions and are a perfect solution for the space savings increasingly requested by customers. The letters “E” and “G” indicate the flow direction, with “E” variants blocking the flow in the screw-in direction and “G” variants blocking the flow in the opposite direction.

The valves fit the market-standard cavity with 118° tip angle (REG-O5-E/REG-05-G). This means that valves from previous series and from other manufacturers can usually be replaced without difficulty. Regardless of the flow direction, only one tool is required, reducing tooling costs. Both of the new KB variants are available in sizes 04 to 16 and for a maximum operating pressure of 350 bar. The RKVE-KB valves open at a pressure of 0.2 bar and allow flow rates of up to 210 l/min. The RKVG-KB variant with the opposite flow direction is available with an opening pressure of 0.2 bar and a maximum flow rate of 170 l/min. Customized adaptations can easily be provided.

The prices for the short-design valves are the same as for the standard design and are at the usual market level. However, their quality and design ensures lower total cost of ownership – a much more significant expense. The valves’ high reliability over long periods considerably reduces repair and maintenance requirements and expensive downtimes.

Competence Center for check valves

Bucher Hydraulics Dachau is the global Competence Center for check valves. In-house development and production ensure the highest level of expertise in all aspects of these components. Over and above the standard product series that meet high technical standards and are available ex-stock at all times, the company also provides special solutions for non-standard industrial and mobile applications, which are developed in close cooperation with its customers. A modular system ensures that these solutions can be developed in a short time at marketable prices. The product range includes screw-in and slip-in check valves, including the new short series, as well as surface-mounted check valves in SAE design. Application-oriented system solutions in which several check valves are integrated into one block for use in power units, municipal vehicles, and agricultural and construction machinery are also available. The Bavaria-based experts provide customer support right through to commissioning and joint tuning of the machine. The Competence Center is backed by the Bucher Group which ensures smooth supply to customers thanks to its worldwide sales and service organization.

Leading in terms of Delta P and flow rate

The RKVE-VD valve series (VD = improved flow) constitutes a milestone in check-valve development for the Competence Center. The experts at the Center put the previous check-valve design under the microscope and were able to achieve a flow rate increase of up to 50% compared to the standard version, all while maintaining the same pressure differential. This not only saves energy, but in many cases it also enables the use of smaller nominal valve sizes. At the same time, it lowers costs and requires less installation space. The valve body and seat are press-fitted together and, like the ball, are hardened. All valves are endurance-tested.

No soft seal means increased flexibility

Instead of the typical soft seal, the new Bucher ball check valves use a metal cutting lip. This makes the valves suitable for use in a much wider temperature range. Plus, without sensitive sealing materials, the valves can be used with a greater variety of media, such as gas or air. Stainless-steel valves are available for applications with media that cause rust. In general, the Bucher Hydraulics ball check valve is particularly insensitive to contamination – which is especially beneficial for mobile and agricultural machines. Even in the standard design, the valve seat, ball, and body are hardened.

In addition, all RKV valves are particularly energy efficient. As a member of the Blue Competence sustainability initiative of the mechanical and plant engineering industry, this has been a top priority for Bucher Hydraulics for many years. Only products that meet specific environmental criteria qualify for the “ECOdraulics” Bucher label. One such product is the ball check valve series which features a low Delta P loss while providing high flow rates. A benefit that is becoming increasingly important in today’s world, it contributes significantly to future-proofing Bucher Hydraulics ball check valves.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.