CONEXPO/CON-AGG 2023 has led us to get to know in person new companies and discover the latest product releases. In this case, we have had the pleasure to chat with Braden Cammauf, FPT Industrial North America VP, who gave us some more details about the newest F28 Hybrid Engine, available for construction and industrial applications. During our interview, Braden gave us a complete insight into FPT Industrial Tier 4 Final and Stage V engine range solutions and shared with us the company’s vision for future steps into the construction industry. Full interview and article below.

FPT Industrial, the world-leading manufacturer of low environmental impact solutions, presented its full range of Tier 4 Final and Stage V, 2.8-to-16 liter engines at CONEXPO CON/AGG 2023, the largest construction show in North America held from 14 to 18 March in Las Vegas.

Renowned for their high performance, flexibility, reliability and maximized uptime, these highly productive and efficient engines can be used across several applications (off-road, and power generation) in a fully sustainable way since they are compatible with renewable diesel fuels (HVO).

At CONEXPO CON/AGG 2023, FPT Industrial aims once again to demonstrate that state-of-the-art engine technology, cost-conscious efficiency and focused sustainability, linked by ingenious design solutions, can be the ace-in-the-hole to meet all the power needs of the construction industry.

NEW F28 FAMILY – MODULAR AND MULTI-FUEL DNA

Size down, performance up. That could be the slogan of the new F28 engine family whose main distinctive feature is the capability to provide the performance of 3.4 liter engine in a 2 liter package, thus resolving the apparently impossible dilemma posed by lack of space and need for high performance. And if that wasn’t enough, the F28 is born with multi-fuel design that shares common base components for the diesel, natural gas and hybrid versions. Available for both construction and industrial applications, F28 versatile design makes it ideal for equipment also in the rental industry, such as aerial lifts, telehandlers, pumps, welders, chippers, and trenchers.

F28 PowerPack – Good things come in small packages

At CONEXPO CON/AGG 2023 FPT Industrial introduces the F28 PowerPack version, completing its already wide offering of pre-assembled, ready to use solutions. The new F28 PowerPack delivers best-in-category performance in an extremely compact and pre-validated package, including all key after-treatment components, thus simplifying the overall installation phase.

Oil change intervals of 600 hours contribute to further lowering operating costs.

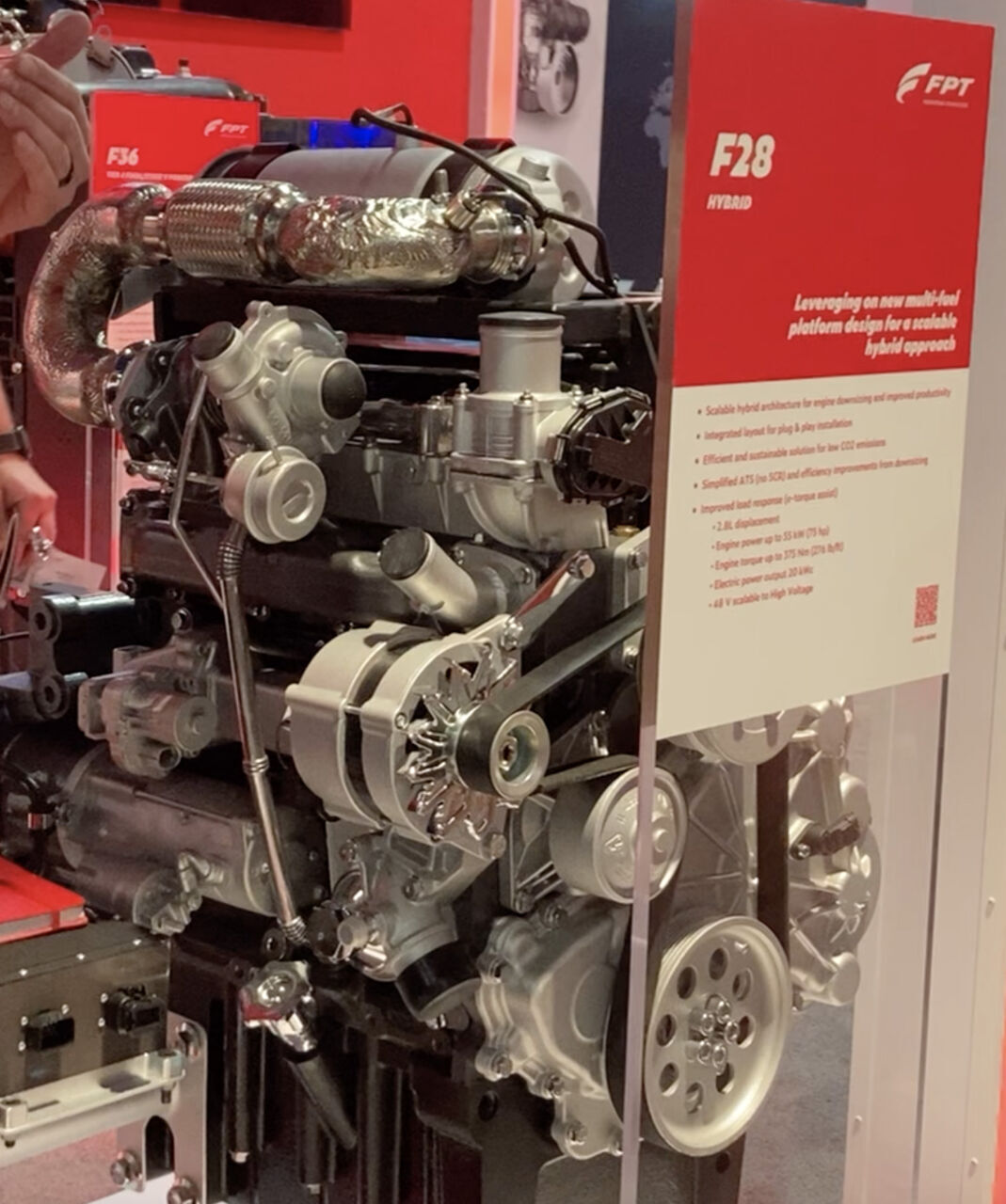

F28 Hybrid concept for construction applications – Built to be sustainable

The F28 Hybrid represents a further step towards sustainable solutions for FPT Industrial. Guaranteeing a low level of CO2 emissions and an integrated package, the F28 Hybrid enables the introduction of electrification on construction equipment applications. Featuring an internal combustion engine compatible with renewable diesel paired with an e-flywheel, this compact yet powerful hybrid powertrain combines high performance and low fuel consumption, making it suitable for compact construction equipment and rental units.

The engine on display at ConExpo 2023 delivers a maximum power of 75hp, with the 48V electric motor that adds 27hp of continuous electric power and up to 40hp in peak power.

The F28 scalable architecture is designed for modular extension to high voltage and based on FPT Industrial’s proprietary control software, reinforcing the Brand’s role as a full systems integrator.

INNOVATIVE AND PATENTED ATS TECHNOLOGY – SUPERIORITY AND PRACTICALITY ACROSS THE POND

Whatever the continent and the latest emission regulations, FPT Industrial not only has the specific solution that fits, but also offers dual-certified systems enabling cross-regional installations. All deliver best-in-class efficiency and minimized downtime in all applications.

For the North American market, FPT Industrial presents dedicated solutions with Tier 4 Final no-DPF technology (HI-eSCR system), while global applications are addressed with integrated HI-eSCR2 system compliant to the more stringent EU Stage V regulation and dual-certified for Tier 4 Final.

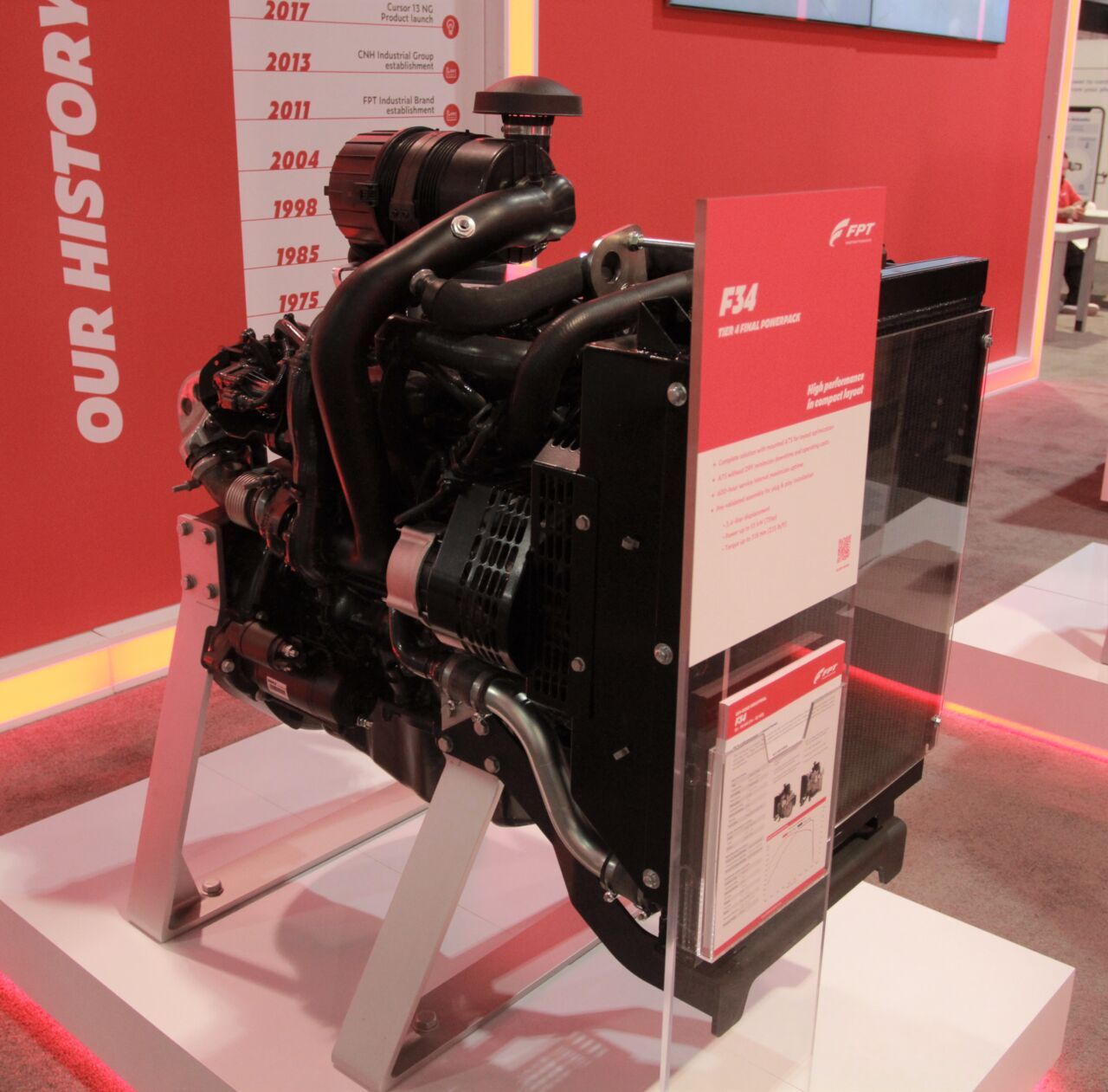

F34 TIER 4 FINAL POWERPACK / F36 TIER 4 FINAL/STAGE V POWERPACK – HIGH PERFORMANCE IN COMPACT LAYOUT

The F34 PowerPack Tier 4 Final stands out for low operating costs and extremely easy maintenance in a compact layout. This solution with mounted ATS shown at CONEXPO allows for layout optimization and plug&play installation. The Tier 4 Final compliant ATS, without DPF, minimizes engine downtime and operating costs with a 600 hour service interval.

F36 Tier 4 Final / Stage V PowerPack – High power density, low fuel consumption

The F36 PowerPack Stage V is part of FPT Industrial’s comprehensive Power Units offering. It represents a powerful, flexible and reliable solution for stationary and semi-stationary applications. The compact ATS pack mounted on the engine, including the urea injection system and all required sensors and manifolds, eliminates the need for a dedicated exhaust system development. A range of options such as alternators, starters, water and air preheating, and different urea tank sizes provide further flexibility for customer installations. Single-side access allows for easy and quick maintenance, while 600-hour service interval maximizes uptime.

N67 TIER 4 FINAL/STAGE V POWERPACK – DESIGNED FOR HEAVY-DUTY APPLICATIONS AND HARSH CONDITIONS

Developed to satisfy the most demanding customer requirements, the N67 PowerPack is the perfect proof of FPT Industrial’s technological excellence. The maintenance-free ATS, featuring Hi-eSCR2 technology for Stage V, maximizes uptime and reduces operating costs. The EGR-free combustion and single stage turbocharging solution maximizes power, optimizes fuel efficiency, and enhances reliability thanks to its lean engine layout. The pre-assembled, pre-wired and pre-validated ATS Pack is the best solution for flexible, fast and easy installation and labor savings. The 600-hour service interval minimizes downtime and FPT Industrial’s “for life” maintenance-free technology guarantees maximum uptime.

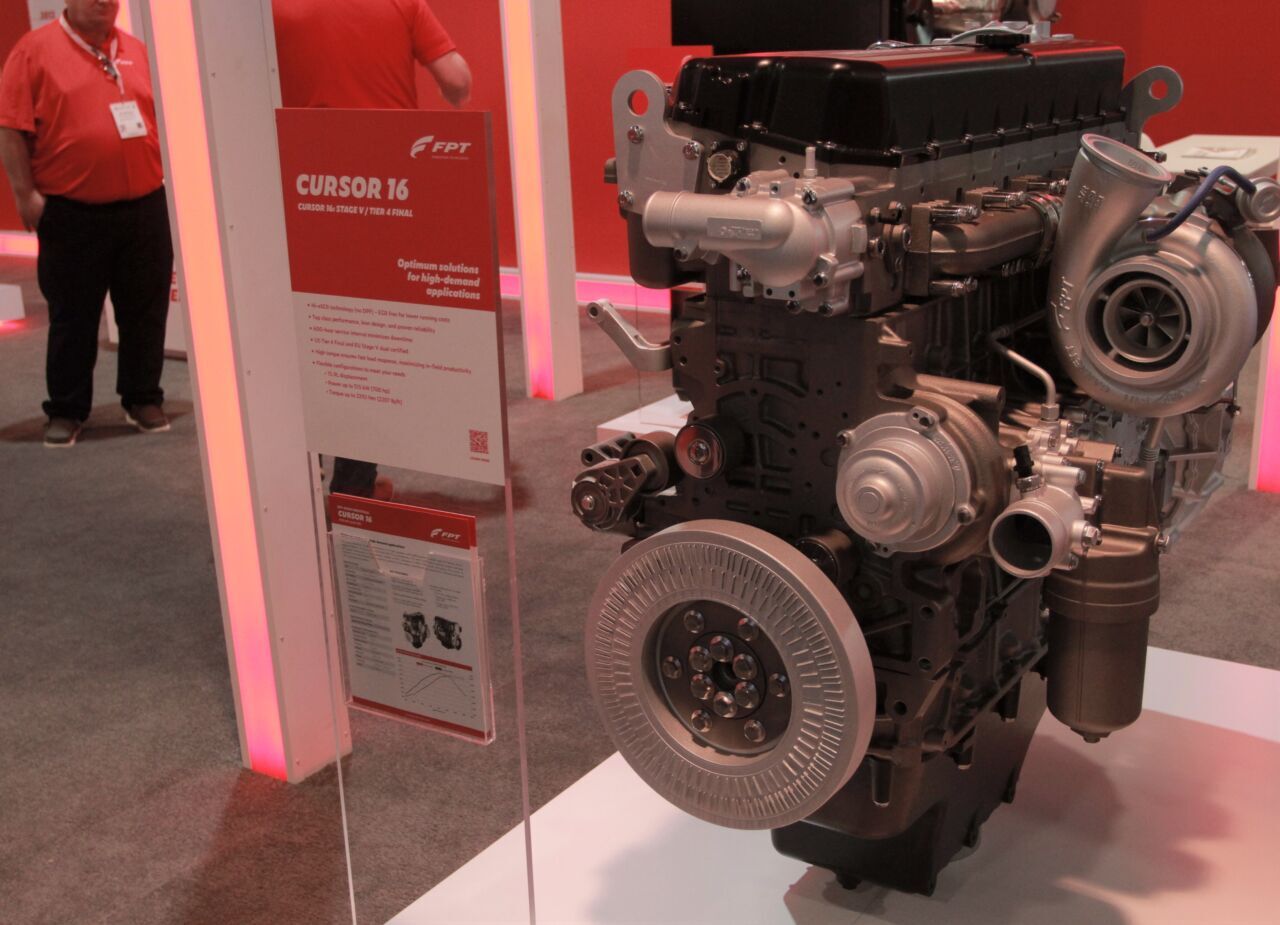

CURSOR 16 TIER 4 FINAL/STAGE V – OPTIMUM SOLUTIONS FOR HIGH-DEMAND APPLICATIONS

Awarded as Diesel of the Year at its debut, Cursor 16 is the flagship of the Cursor range, with 15,9 liters displacement and delivering 18 liters-like performance in a 13 liters package, with leading power-to-weight ratio (0,5 hp/kg). 2200 bar common rail system, innovative ball-bearing turbocharger, high-resistance cylinder head in compacted graphite iron (CGI) and more than 20,000 hours of bench test specifically dedicated to off-road missions, make the Cursor16 a strong, reliable yet compact solution.

High torque availability ensures fast load response, maximizing in-field productivity, while 600-hour service interval minimizes downtime.

ALTERNATIVE FUELS COMPATIBILITY – A FULL TANK OF SUSTAINABILITY

All FPT Industrial Tier 4 Final and Stage V engines presented in Las Vegas are fully compatible with renewable fuels (e.g., HVO). Combined with FPT Industrial proven ATS technology, these fuels are low impact solutions, achieving net-zero CO2 emissions.

THE BEST SERVICE, OUR CONNECTION WITH YOU

Through a worldwide dealer network and implementing the latest technologies, FPT Industrial delivers its customers 360-degree professional assistance in order to maximize uptime, minimize TCO and prevent any possible issue. Across the US and Canada, FPT Industrial stands by its customers with a complete distribution network featuring fully engaged and continuously trained partners delivering the best products, the fastest assistance and the most professional advice.

FPT Industrial Customer Service offers 24/7 support, the MyFPT app and an extended warranty, which solidify brand commitment to 360-degree customer service and support. The MyFPT app brings customers information at the tip of their fingers, along with quick, efficient, and tailored support. Through connecting the plug-and-play FPT Industrial dongle to the machine engine diagnostic port, and the MyFPT app via Bluetooth, it is possible to gather live engine data.

“Just as we have re-launched our complete power generation line-up for the North American region in the last 2 years, we are here this year at CONEXPO to do the same with our construction line-up. We have been working with our distributor partners, rental companies, and our customers in order to have on display today powertrain solutions that provide the best performance, packaging flexibility, after treatment solutions all with great savings in terms of fuel consumption. With our full portfolio which consists of ICE, Alternative Fuels, Hybrid, Batteries, Electrified Drivelines, Hydrogen we will position ourselves to be a partner for all your short and long term needs.”

says Braden Cammauf, Vice President FPT Industrial North America.

The post A Conversation with Braden Cammauf, FPT Industrial North America VP: Wide Engine Ranges for Several Application Fields appeared first on USA HeavyQuip Journal.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.