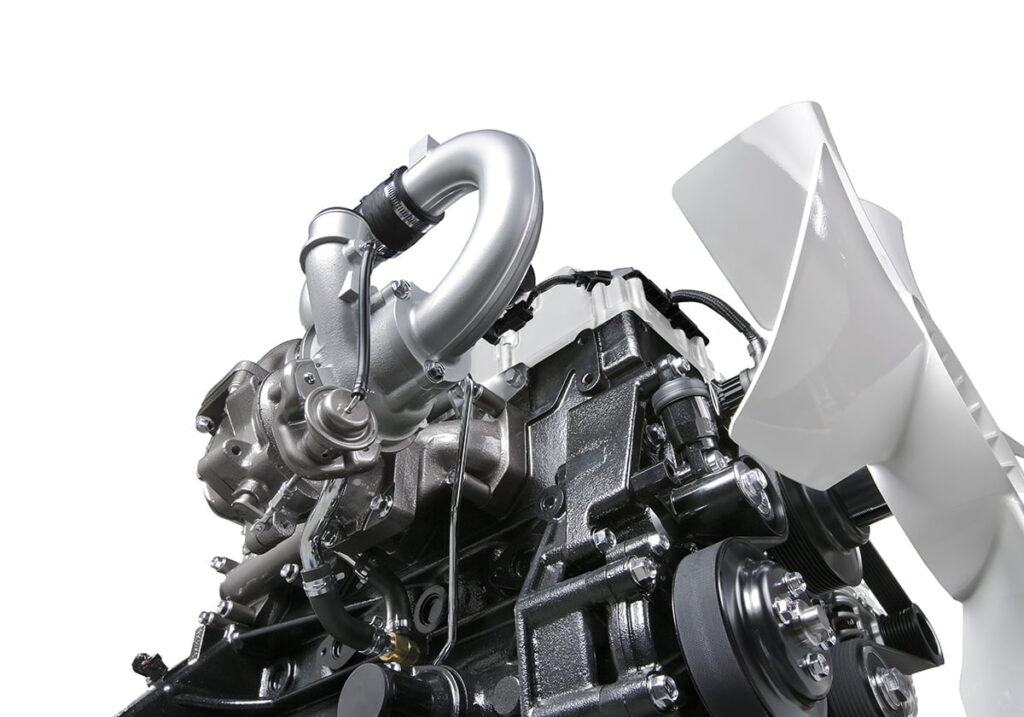

As manufacturers of construction equipment and powertrains evolve in the transition from traditional combustion engines to battery power, the focus on system integration and tailor-made solutions is now more critical than ever.

At bauma 2022 in Munich, Germany, Yanmar, a leading provider of power solutions and industrial machinery, showcased its electrification strategy for off-road vehicles and equipment.

Here, Yanmar board member Ms Shiori Nagata outlines how the company is dedicated to contributing to a carbon neutral future, offering optimum solutions for its customers and becoming an all-in-one electrification system integrator.

There’s evolution in the world of construction machinery and powertrains in the drive towards a carbon-neutral future.

Manufacturers of equipment and power systems are in the midst of a huge transformation from traditional combustion engines to a new world of battery power, electric powertrains and the use of a range of alternative fuel technologies.

But this new scenario brings with it fresh challenges for OEMs and power systems’ suppliers.

Yanmar said that forging even stronger partnerships and collaborations with all of its stakeholders in the industry is crucial during this period of power evolution – stakeholders such as the company’s customers, dealers and OEMs.

“Over the past 110 years, Yanmar’s core values have been durability, reliability, quality and robustness and, today, a commitment to creating a sustainable future is our brand statement.”

said Nagata.

Mr. Carlo Giudici, Yanmar Europe Sales Director EMEA, added:

“We have a new electrification strategy which encompasses a portfolio of new-energy technologies and products all based around an emphasis on teamwork and co-operation with our partners. Yanmar is positioning itself as the one-stop, all-in-one systems integrator of e-powertrains for off-road equipment. Working alongside Yanmar, OEMs can focus on their core business and challenges and, confidently, outsource all electrification-related power issues to us. Yanmar is evolving into an advanced supplier of electrified solutions able to design the optimum, tailor-made, e-solution which is specific to the individual requirements of each OEM. We will build optimal control systems for our OEM’s equipment, provide remote monitoring for an overview of each product and offer full after-sales service worldwide. This approach also means that we are supporting our OEM partners and customers to achieve their own environmental and performance goals. Togetherness is at the heart of how we want to work with our OEM partners.”

Yanmar said that by working with a company as its system integrator, OEMs receive an integrated solution for smart electric powertrains tailored to the specific needs of their individual applications – from its design, including concept proposals, to system control, system evaluation, procurement, manufacturing, quality assurance, and after-sales service.

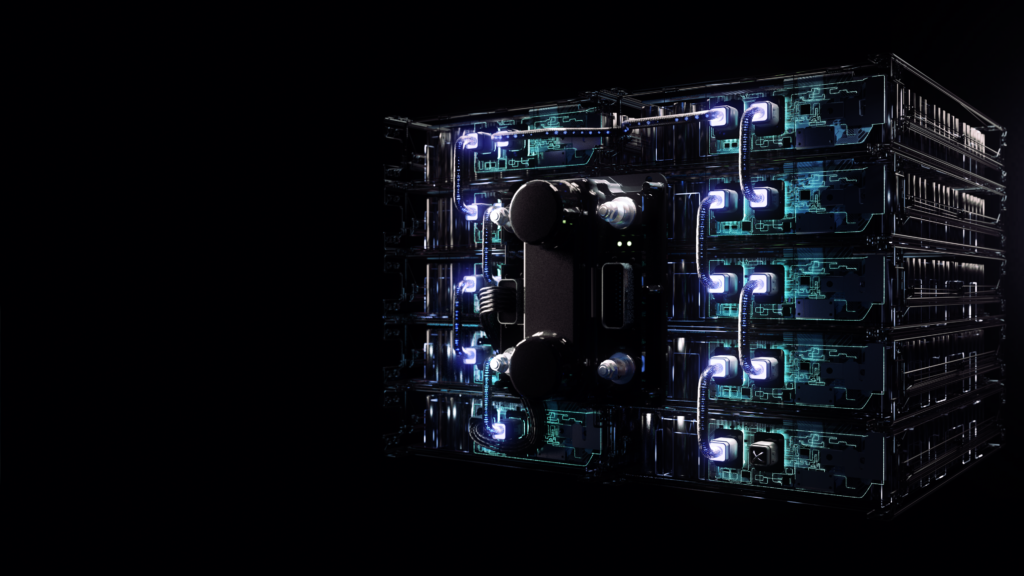

As well as introducing a new Yanmar electric powertrain at bauma 2022, the company also showed an electrified demonstration vehicle that exhibited the practical application of the company’s system integrator technologies.

Yanmar digitally showcased system integrator applications technology, integrating power and control systems with advanced applications management in a versatile and easy to use sample machines.

In another move towards implementing its electrification strategy, in April this year Yanmar announced it has acquired a majority share in ELEO Technologies B.V., a fast-growing battery technology company based in Helmond, the Netherlands.

By integrating ELEO’s advanced, scalable, and modular battery technology, Yanmar said it will further its electrified powertrain capabilities with versatile, customised solutions for off-road applications.

To serve its growing customer base, ELEO will open a new state-of-the-art production facility later this year increasing annual battery production tenfold to 500MWh – equivalent to approximately 10,000 battery packs.

At bauma, ELEO introduced its newest generation product developed specifically for OEMs with high mix, low-volume applications.

Mr Bas Verkaik, a co-founder of ELEO, said:

“ While electric cars were clearly starting off, we saw that the uptake of industrial vehicles kept lagging behind enormously. We saw that the challenges faced by these OEMs were completely different as opposed to the car manufacturers. While car manufacturers can build a dedicated battery system for hundreds of thousands of the same or similar vehicles, manufacturers of off-highway machines need a thousand battery systems for a thousand different machines. And this while the performance and endurance requirements are even more stringent. We are very happy to have partnered with Yanmar earlier this year. Together with their ambitious electrification vision we are in the unique position to spread our technology towards OEMs around the globe and thereby accelerate the adoption of electrified powertrain systems worldwide.”

Asked about Yanmar’s future electrification roadmap Giudici said:

Asked about Yanmar’s future electrification roadmap Giudici said:

“In the next months we will further develop our e-powertrain solution. Furthermore, we are giving ourselves another challenge this year – The Yanmar Green Challenge 2050. It is a declaration and a challenge we impose on ourselves to become a company that achieves zero greenhouse gas emissions and a zero ecological footprint by recycling resources. This is a comprehensive challenge to become free of greenhouse gas emissions and ecological footprint in not only our own activities but also to realise zero greenhouse gas emissions and the recycling of resources among our clients’ activities with which we are associated. Because we are committed to realising a sustainable future we will think and take action in concrete terms beyond the scope of our own activities It is an action plan that will contribute to society as a whole.”

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.