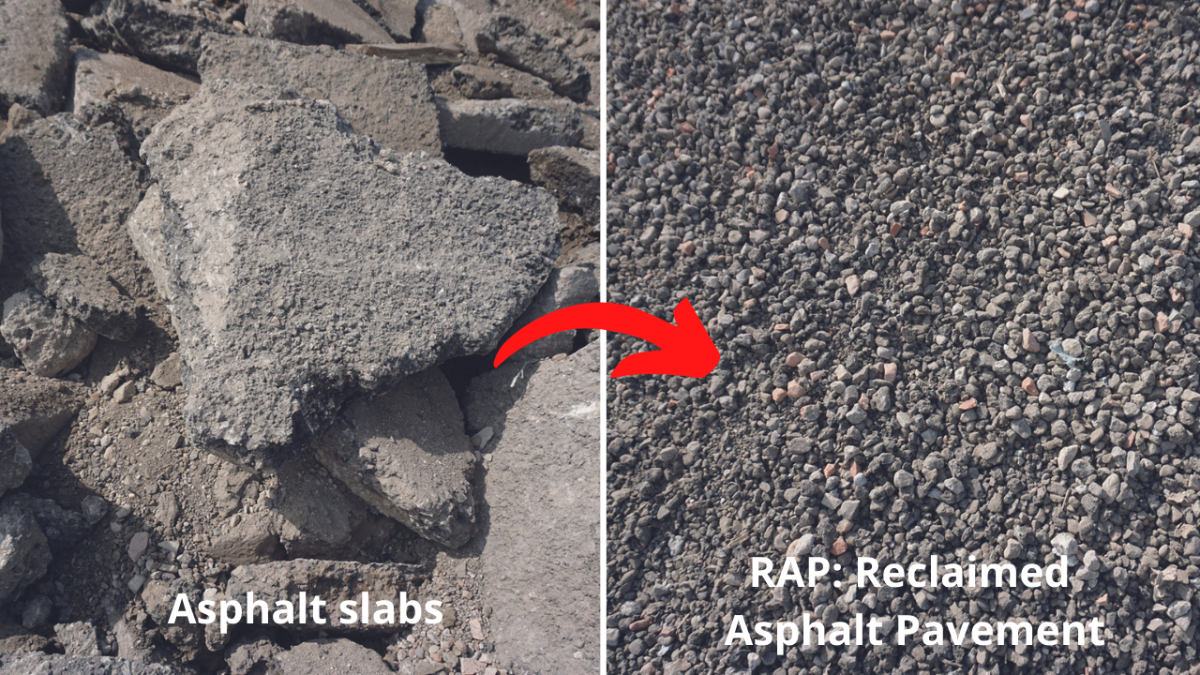

Available in 2 models for excavators from 18 to 40 tons. CBA asphalt granulator buckets are specifically designed for the volumetric reduction of asphalt slabs (or other aggregates) to a certifiable and measurable granulometry, directly on site.

Simex has chosen to focus on the recycling of asphalt milling, more correctly called today bituminous conglomerate granulate by the legislation (RA or RAP – Reclaimed Asphalt Pavement) beginning from its expertise in the field of crushing and screening waste materials from demolition.

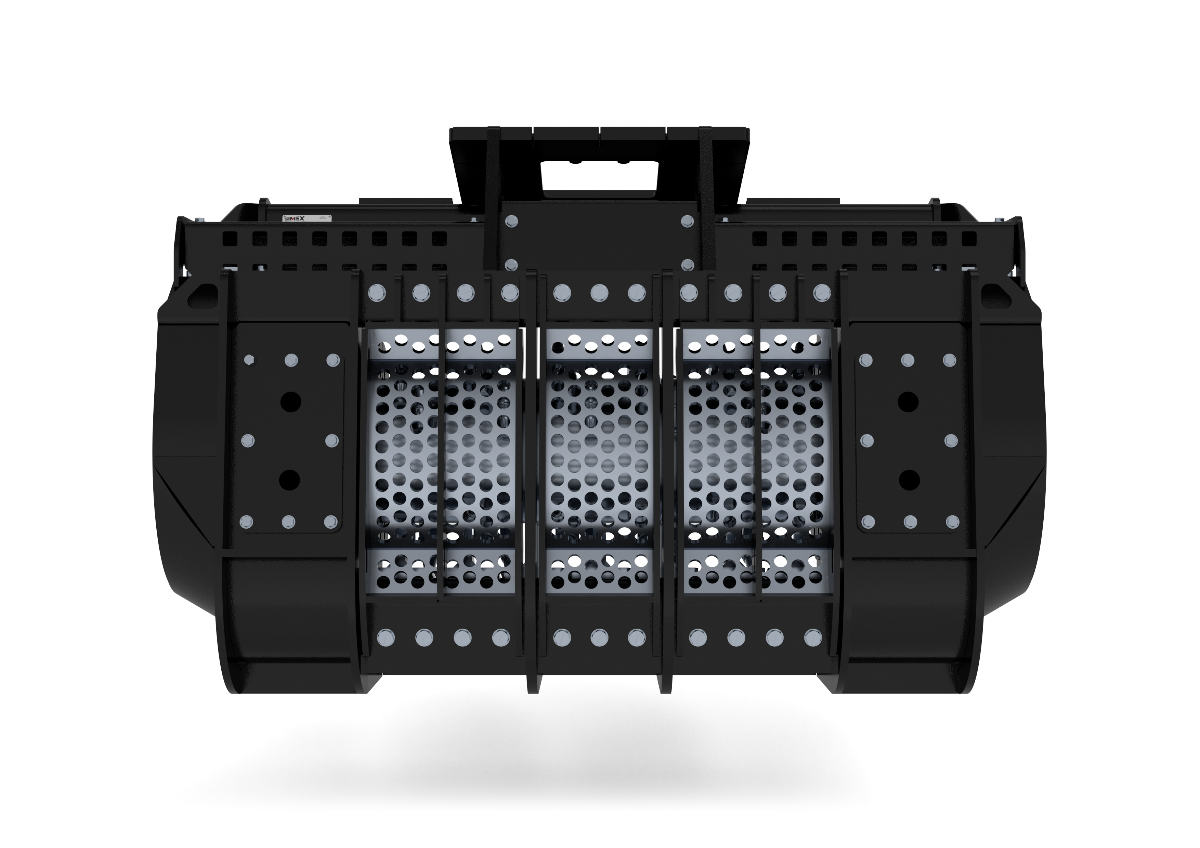

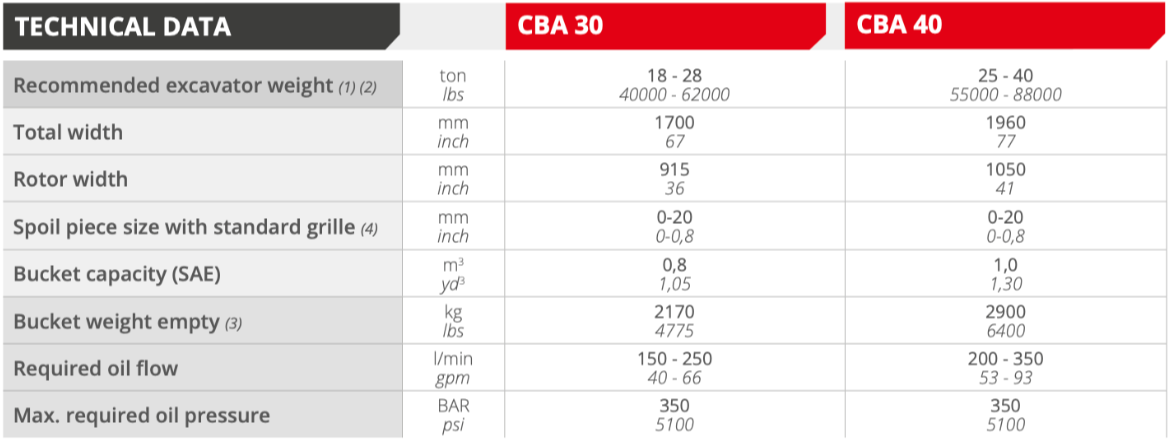

The asphalt granulator bucket is available in 2 models: CBA 30 for 18 to 28-ton excavators, and CBA 40 for the 25 to 40-ton range. The equipment features a cylindrical drum consisting of interchangeable teeth, driven by large displacement radial piston hydraulic motors, in direct drive.

The asphalt granulator bucket is available in 2 models: CBA 30 for 18 to 28-ton excavators, and CBA 40 for the 25 to 40-ton range. The equipment features a cylindrical drum consisting of interchangeable teeth, driven by large displacement radial piston hydraulic motors, in direct drive.

The rear grid determines the grain size of the material output and is available in several configurations, to meet the different characteristics required for the milled material by the regulations in force in various countries. Size of the output material with standard grid: 0-20 mm

Environmental protection while cutting down the costs

The CBA asphalt granulator buckets aim to ensure broad autonomy for operators engaged on a daily basis in road maintenance works, crushing aggregates and filling excavations for laying underground utilities. Cutting down the time and costs related to transport, minimizing the purchase of new raw materials, means optimizing the logistical and economic dynamics of your site, while keeping a watchful eye on the issue of environmental impact and the recovery of those materials which, subject to specific local regulations, could be considered a resource and no longer waste.

From cold milling, with the wide range of road planers, to the crushing and volume reduction of aggregates, Simex can now offer multiple solutions for recovering bituminous conglomerate on site.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.