People and freight on trains are not the only things traveling through the Channel Tunnel. A high-voltage cable now ensures a safe exchange of electricity between Great Britain and France. To make sure that the cable is on no account damaged, special service equipment is necessary.

“Today the scissor lift platforms arrived and immediately turned heads,” writes Carl Jones of GOS Tools & Engineering Services to Palfinger Railway. “They are so impressive. They are so much better than they looked at the Teams presentations. The love of detail is a hallmark of Palfinger.” The 16 PA1500 scissor lift platforms are custom-made.

European artery

And custom-made equipment was what was required for this special job. The Channel Tunnel has connected France and Great Britain for 27 years. Now it is taking on another task as part of the trans-European power grid. A high-voltage direct-current power cable is being laid through the tunnel that will play a vital role in securing the power supply to and from Great Britain and France. Laying the cable is fast and straightforward thanks to the existing infrastructure. It is protected from the elements, and down in the tunnel there is nothing that could harm it and consequently compromise the electricity supply.

Risk factor maintenance

Or is there? A risk assessment carried out by the management of Eurotunnel came to a different conclusion. The cable can be damaged by collisions with access platforms or a crane in the course of maintenance work or inspections in the tunnel. However, this potential danger can be proactively eliminated – if service equipment with horizontal and vertical movement limiting devices that meet PLd (Performance Level d) in line with the EN 13849 safety-related standard is purchased. That was the task entrusted to GOS and Palfinger.

The British company GOS Tools & Engineering Services and Palfinger Railway have enjoyed close cooperation for many years. Having successfully completed numerous projects together the two companies have built up a partnership based on deep and sound trust. This trust was to prove crucial on this project in particular because no one could have legislated for COVID year 2020 and all the challenges it presented.

From a pilot project…

Project development started in early 2019 as a pilot project of the Palfinger development process (PDP). In close cooperation and consultation with the British partners at GOS, initial field findings and corresponding feedback were gathered. The COVID pandemic meant that acceptance often had to take place virtually, using Microsoft Teams. But despite COVID there was never any doubt that the project would be concluded successfully and on time.

… to the fully developed small series

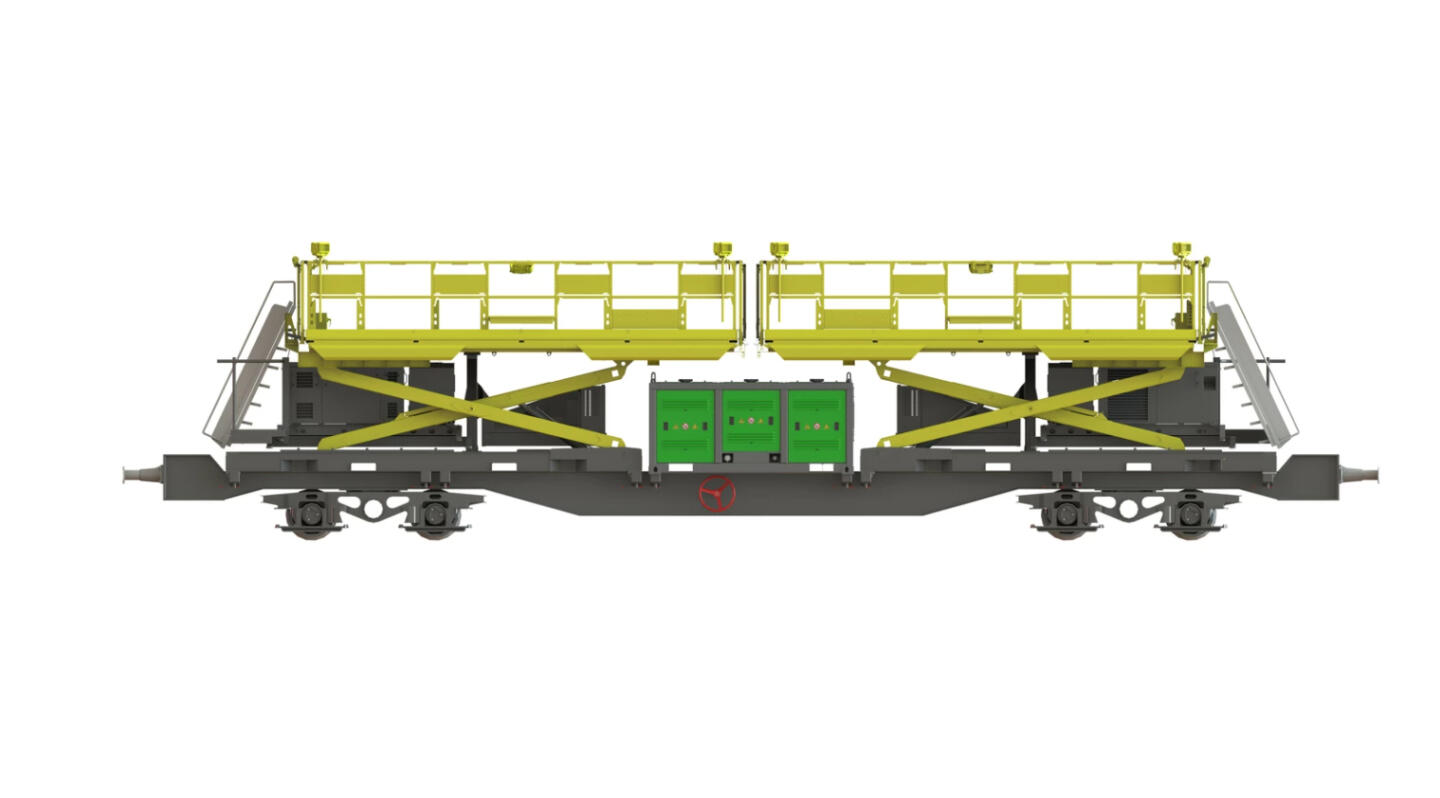

The result is the PA1500 scissor lift platform, a tailor-made small series for use in the Channel Tunnel. The platform has a safe working load of 1.5 tons and can work at an inclination of up to 10° when fully laden. The basket is six meters long, and the width is adjustable from 2.9 to 4.5 meters, giving a maximum working space of nearly 30 m². The platform’s modular construction means it can be installed on a wide variety of vehicles. By engaging synchronous operation mode, every movement of two scissor lift platforms mounted one behind the other can be steered simultaneously using a remote control.

Solution-driven and customer-specific

Apart from the PA1500 platforms, the order also includes two PA 200 platforms, two PKR 800 railway cranes, six PR 220 cranes incl. BB 29 and BB 49 baskets, and other equipment with a total value of several million euros.

“GOS knows that we deliver top quality, always focus on solutions and adapt our work to each customer’s requirements,” says Christian Prantl, Head of Sales Palfinger Railway. “A strong partnership and genuine mutual trust are the key elements in this project’s success.”

Source: Palfinger

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.