Ktwo is focused on continually improving its product range to maximise versatility and longevity, recently with new agricultural trailer silage sides design.

Ktwo has always invested heavily in its product design and has increased its design engineering team by three in the last year alone. It is continuing to focus on product innovation based on customer feedback, precision, efficiency, and the most up-to-date technology.

Ktwo trailer silage sides are designed to give farmers the flexibility with materials without needing to increase their trailer fleet.

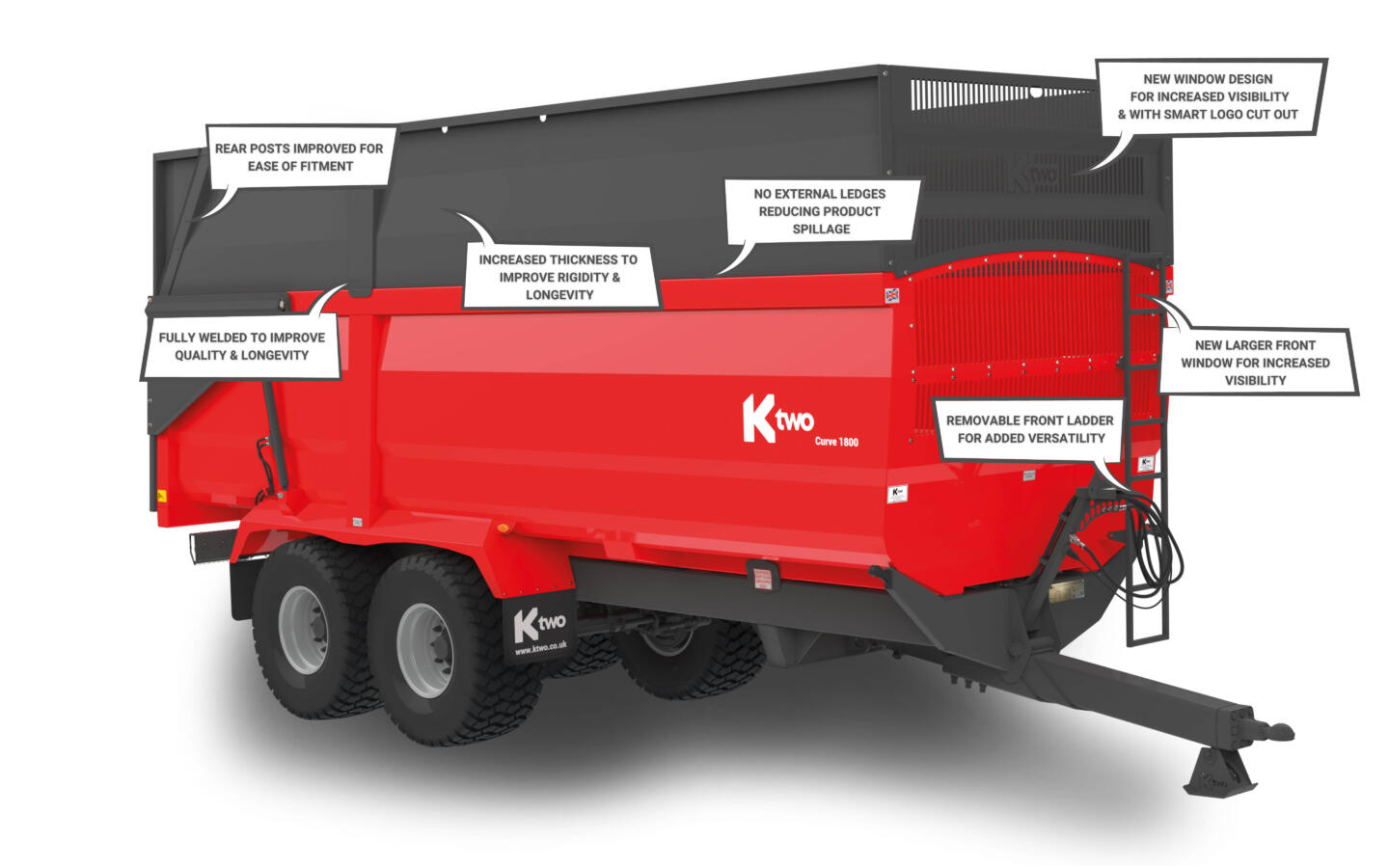

The new and improved silage sides have been designed to ensure there are no external ledges, reducing any spillage of product onto the road to improve efficiency and road safety.

Ktwo’s Roadeo Curve Trailer range has a unique body design built from a single sheet of high tensile steel for increased strength and a lower nett weight. The new silage sides have been improved to follow the Curve’s strength in its design and build quality.

The silage sides have an increased side thickness from 2mm to 3mm to improve rigidity and longevity.

“Our silage sides are fully welded to improve quality. This allows for an excellent paint finish and product longevity.” Explains Chris Gordon, Design Manager.

“The new silage sides have no external lip so when loading there is no risk of product remaining on the outside of the trailer.”

Ktwo have made further improvements in the rear trailer posts to improve fitment and making it easier to take the sides on and off.

Coupled with the new Ktwo Roadeo Curve Trailer front window which gives increased visibility and the removable front ladder, Ktwo trailers are now more versatile then ever before to ensure maximum efficiency.

The new design also features the bold Ktwo logo cut into the front panel of the silage sides which really makes the new design standout.

The first Ktwo Roadeo Curve Trailers with the new and improved silage side designs have left the factory and are being very well received by customers.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.