Our staff attended at Manitou digital event “Build the Future”

***

Manitou has unveiled the new segments in its construction range with new compact fixed and ultra-compact telehandlers, as well as new articulated loaders. The group also ushered in a complete overhaul and extension of its range of rotating telehandlers at the digital “Build the Future” event broadcast worldwide.

In order to offer a unique, 100% digital launch, Manitou organized the “Build The Future” event. Accessible via an interactive platform, the event brought together more than 3,000 internet users in 90 countries across 4 continents, including many dealers, rentals, key accounts and media. Over the course of two days, visitors were able to remotely discover, through a talk show, three new segments in the construction and MRT rotating telehandler range, followed by workshops showcasing the group’s commitment to supplying comprehensive and durable solutions while providing its customers with a premium service.

Fully redesigned MRT rotating telehandlers

The manager, explains this change:

“We are seeking to harmonize our entire range by making it simpler. By modernizing the design and ergonomics of our products, we are now able to offer a single cab across all the models in the range, thus providing excellent visibility to users whatever the model. Having the same cab also means having an equivalent control station on all models, making them quicker to get to grips with”.

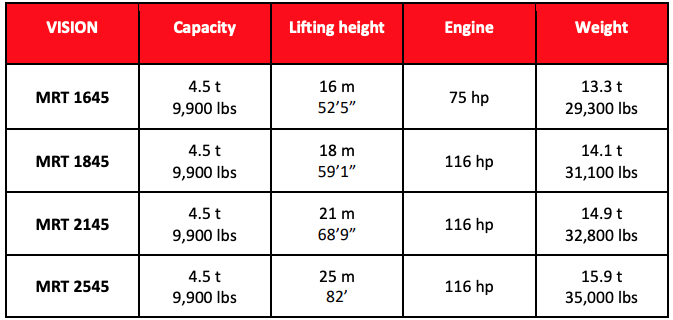

Two new machines have been added to this offering with the MRT 1645 and MRT 1845 models for the Vision range. With 500 kg (1,100 lbs) of additional load capacity compared to their predecessors, these two products offer a lifting height of 16 meters (52’5”) and 18 meters (59’1”) respectively for a load of 4.5 tons (9,900 lbs). They are also equipped with a new Stage V engine, producing power of 75 hp and 116 hp respectively. The Vision range offers a wide selection of 14 models with heights ranging from 16 meters (52’5”) to 25 meters (82’), for a load capacity of up to 4.5 tons (9,900 lbs).

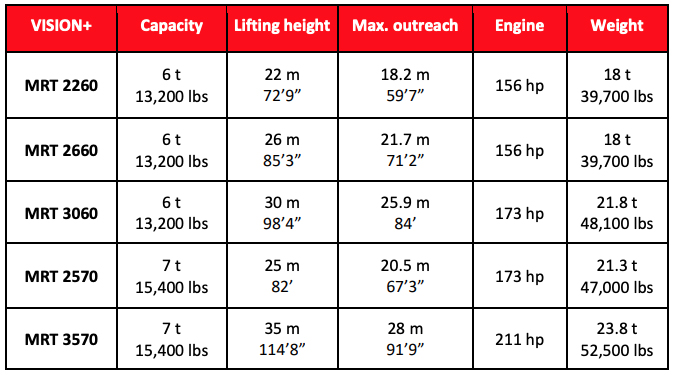

The highest capacities are grouped together in the Vision+ range, which features 12 new models. The range has been completely revamped with six new products: MRT 2260, MRT 2660, MRT 3570 (also available in an electronic suspension version), MRT 2570, and MRT 3060. Carlo Alberto Razzoli explains the reasons behind the renewal of the range:

“There is growing demand from customers wanting machines that offer higher performance on construction sites. This high-capacity range meets these expectations perfectly with a very high level of equipment”.

With models offering a lifting height of 22 meters (72’9”) to 35 meters (114’8”) and a much improved capacity of up to 7 tons (15,400 lbs), this range is ideal for the installation of structural steelwork, renovation of buildings, and even demolition. These two ranges are connected as standard in order to optimize maintenance, increase the machine’s operating hours and therefore reduce the total cost of ownership for the user. The Vision and Vision+ ranges are now available worldwide and will be delivered to the dealer network, to rentals and to key accounts by September 2021.

MRT specific attachments

New attachments, designed by the Manitou Attachment Competence Center (ACC) based in Italy, accompany the launch of these two ranges. Two CAF 1030 (6 tons/ 13,200 lbs and 7 tons / 15,400 lbs) and CAF 1080 (7 tons / 15,400 lbs) floating fork carriages will benefit users needing to handle pallets or big-bags with optimum visibility. They are lighter and more robust, and are fitted with a fork locking system.

The performance of winches, jibs, and cranes is enhanced with a winch equipped with a new hydraulic motor suited to the new MRTs. With a capacity ranging from 600 kg (1,300 lbs) to 2 tons (4,400 lbs), they meet the requirements of the new MRT range perfectly. A new 100% aluminum platform is now available across the whole VISION+ range. Weighing just 180 kg (396 lbs) for a loading capacity of 365 kg (805 lbs), the PSE 4200/365 is lighter than the previous range, allowing a greater outreach. It also features easy opening. These new attachments have been designed based on customer feedback in order to help them optimize their operations.

Innovative equipment for increased productivity

The Vision name was also chosen to convey the idea of in-cab visibility. To further increase visibility, a reinforced gridless roof, certified to ROPS/FOPS level 2, is available as an option for closely monitoring loading operations at height. Present on all Vision and Vision+ models, the pressurized cab guarantees a healthy working environment for the operator and additional sound insulation, for greater comfort.

Another innovation presented by the group is a new optional driving remote control for controlling the machine from the basket or when the operator is outside the machine. As a result, it is possible to move it safely without having to return to the driver’s cab, saving precious time on site. A new hydraulic pump is fitted on all of these new models. With a hydraulic flow of 116 l/min, the Vision range ensures an execution speed 50% quicker for simultaneous boom movements. This improvement rises to more than 30% for the 2260 and 2660 models in the Vision+ range, which are equipped with a pump that delivers a flow rate of 185 l/min. The new Stage V engine also helps to reduce the consumption of all of these models with a power of between 156 hp and 211 hp depending on the model. The lifting capacities and load charts have been significantly improved, most notably the capacity at maximum height by up to 100% and at maximum reach by up to 25%. The weight of these machines has been reduced by more than 5% while benefiting from an increase in their load capacity of up to 15%. The group is once again demonstrating to what extent innovation is an integral part of its DNA, with 21 patents filed within the context of the design of these two new MRT Vision and Vision+ ranges.

Safety and ergonomics

The safety of the people using these machines is a priority for Manitou. In order to give operators complete visibility, a pack of five LED headlamps ensures full lighting all around the machine, plus two boom head worklights for excellent visibility during loading operations at height. A rear camera that sends images to the cab allows the machine to be maneuvered in complete confidence. Four accesses built into the chassis, on the left and right, and at the front and rear of the machine, now enable the operator to climb into and out of the machine regardless of which way the cab is rotated. For an optimum experience, the group is reaffirming its intention to offer increasingly comfortable working conditions with evolving cab ergonomics. The brand-new 8″ vertical touchscreen on the Vision range, which comes in a 12.1″ XXL version on the Vision+ range, is a real human-machine interface that prides itself on being able to rival anything in the automotive sector.

The Vision and Vision+ ranges also feature hydrostatic transmission offering greater driving flexibility and giving the operator a maximum speed of 40 km/h, whatever the model. The latest addition to the Vision+ range, the MRT 3570 allows the operator to carry out handling operations up to 35 meters (114’8”), the greatest height available from Manitou. For increased visibility at this height, the group’s R&D and marketing teams have introduced a new electric seat that tilts by up to 18° to easily monitor the deployment of the boom. This model is also available in an “ES” electronic suspension version.

Electric models available from the end of the year

To illustrate its desire to make the ecological transition a strategic priority, Manitou will be offering a full electric extension to the Vision+ range by the end of the year, as well as a hybrid version combining a smaller engine with a lithium-ion battery. Many models will be available, enabling 100% electric use where work sites and regulatory constraints call for it (Greater Paris, indoors, Scandinavia, etc.).

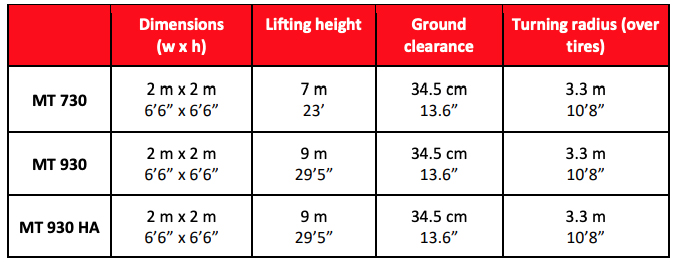

A new segment of compact fixed telehandlers!

Manitou is creating a new segment in its construction range with compact and hydrostatic fixed telehandlers. With three new innovative models, the MT 730 H, the MT 930 H, and the MT 930 HA (with platform basket), the Manitou brand is clearly responding to strong demand from rentals and dealers for compact machines with space on urban construction sites becoming increasingly limited. These compact sizes, 2 meters wide by 2 meters high (6’6” x 6’6”), have a broad selection of equipment. In the cab, the intuitive Harmony screen, with a display available in 22 languages, gives the operator realtime maintenance and usage notifications. This easy-to-use universal dashboard makes it quick to get to grips with and ensures the safety of both the operator and the machine. A new boom with built-in cylinder offers greater visibility for enhanced safety during loading and unloading. With their small size, these three models are easy to transport and can therefore be quickly delivered from site to site. A fork mounting system on the carriage has been designed to further optimize the length of the machine with attachment, thus reducing transport costs. To guarantee precise and flexible movements, these innovative products have a hydrostatic transmission and a 75 hp engine. These three models are now available to order worldwide and will be delivered throughout the dealer network and to rentals and key accounts from September 2021.

One of the lowest TCOs on the market

Reducing the Total Cost of Ownership is a priority for Manitou, whatever the range. The group now offers users of this new range the option to very easily analyze their hydraulic oil. The principle: under the boom, there are two caps for easily collecting the oil, simplifying maintenance and reconditioning or dialysis of the hydraulic oil. Fleet managers can optimize their oil consumption by avoiding wastage and increasing maintenance intervals. A new solution has also been added to this equipment to reduce the TCO, with the implementation of an optional brand-new innovative Stop & Start solution. Just like in the automotive world, this system automatically cuts out the engine when idling. It can be configured from one minute to 30 minutes and turns the engine back on when the accelerator pedal is pressed or via movement of the JSM, without having to restart by turning the key. The fuel savings made and the noise reductions are particularly significant, with a maximum of 45% idle over the entire usage time of these models. As a result of these innovations, the MT 930 H has an hourly cost of just €18.49*, the lowest cost on the market for this segment.

Enhanced construction site safety

To meet the requirements of restricted or indoor construction sites, these three telehandlers can be equipped as an option with the Safety Pack for optimum safety. This device supports and protects the operator and his or her environment. It warns on-site teams and feeds data back to the fleet manager. Any inappropriate behavior is therefore identified by sensors activating two flashing lights inside and outside the cab, such as movement of the machine with the boom raised, the seat belt not being fastened, temporary activation of movement cut-off, etc. To avoid any inadvertent movement of the machine, the JSM now detects the operator’s hand to carry out hydraulic movements. Another detection tool, a reversing aid, informs the operator if there is anybody behind the telehandler for complete peace of mind during operation. Access to the cab is also optimized for risk-free entry and exit as a result of there being no step. An automatic parking brake with hill-start assist also helps to reduce the risk of accidents.

A multitude of applications

With a capacity of 3 tons(6,600 lbs), the MT 730, MT 930 and MT 930 HA models are perfectly suited to residential construction/renovation work, whether for private homes or buildings with up to two stories. These models also have a new floating fork carriage (CAF 1000/3 LB) with forks that fold up to make traveling on the road and towing safer and easier. A new compact bucket (BGP 2000/800) with 800-liter capacity, specially designed for these models, allows safe movement of loose material with a maximum density of 2,100 kg/m³ (sand, earth, gravel, etc.). All of these attachments have been designed by Manitou Group, the fruit of its design office’s expertise.

Coming soon: a new segment of ultra-compact fixed telehandlers

To further extend its offering, the group will be launching ultra-compact rough-terrain telehandlers 1.90 meters high and 1.49 meters wide (6’2” x 4’9”) at the end of 2021. Previewed at the Build the Future event, these ULM (Ultra-Light Manitou) models boast a weight of just 2,700 kg (6,000 lbs) with standard attachment and can therefore be transported on a standard trailer with no specific permit required. Intended for the construction sector, but also for landscape gardeners or events teams, they will be delivered to the dealer network, rentals and key accounts in early 2022.

A revamped and extended range of articulated loaders

In order to provide its users with the best possible solutions, Manitou is revamping and extending its range of articulated loaders. Available with Stage V engines for Europe and Final Tier IV engines for the US, these new machines feature a new design, accompanied by numerous options to best meet the needs of its customers.

The innovations include a reduced width for moving around rough-terrain sites more easily, an optimized hydrostatic transmission for enhanced comfort, and an increasingly lower TCO. The four compact models, MLA 2, MLA 3, MLA 4, and MLA 5, will be connected and equipped with a short arm for greater capacity and a long arm for applications calling for increased lifting height. They will also be available with canopy or integral cab. These new models will be distributed within the dealer network, to hirers and to key accounts by the end of 2021.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.