Officine Mingozzi has taken part in World Ag Expo with the PTRB 3800/1S IT4 machine for the thermal treatment of the soil.

Operational Characteristics

Weed-killer tool carried by tractor by means of III° point hitch and working by means of LPG gas contained in commercial bins, maximum continuous working width mt. 3,80. The equipment in working conditions can also only be towed by the tractor because the machine itself is equipped with 3 adjustable front wheels. Wheel center distance is cm. 185 and 2 rear rollers and this is to reduce the trampling pressure. The tool is equipped with 36 open flame burners protected by shielding and their security systems. The cylinder holder allows the housing of 4 cylinders of 25 Kg and is complete with a heating system for the above-mentioned. The equipment is complete with 2 side burners for cleaning between the posts of the greenhouse. In addition, the following can be added on request: a side burner kit and two burners for the right side of the machine complete with pipes and connection taps. The machine is controlled by means of a magnetic control unit to be positioned close to the machine site of driving the tractor. The working pressure of the equipment can be checked on this control unit. A control and fault signaling unit with safety devices are installed on the machine.

The machine is suitable for treatment against weeds, fungal diseases, and parasites. The hourly consumption of the machine ranges from 66 to 72 kg/hour of LPG depending on the type of use; while the working speed of the machine ranges from 1.5 to 3 km/hour depending on the type of work, weather conditions, and terrain.

PFVII IT2 is weed control equipment suitable for working in vineyards or orchards with the distance between rows of at least 1.50 m wide. The machine is suitable for suckering treatment, against weeds and fungal diseases. The treatments always take place without ever touching the stems of the plants, working at about 20-25 cm from the center of the row and 20-25 cm from the ground. The maximum working width of the treatment on the ground is 60 cm, the machine consumption per hour is 18-20 Kg/h of LPG, and the machine working speed is from 3 to 5 Km/h.

The other machine is PTRB 1600/1 IT4: pyro-disinfection tool brought by tractor by means of III° point connection and working by means of LPG gas contained in commercial bins, maximum continuous working width m.1,60. The equipment in working conditions can also only be towed by the tractor as it is equipped with front wheels of diameter 400 mm, adjustable in position and height, and a rear flat roller. The tool is equipped with 15 open flame burners protected by shielding and relative safety systems. The cylinder holder allows the housing of 4 LPG cylinders and is complete with a heating system for these cylinders.

Technical Report

Officine Mingozzi has committed itself to the development of a series of machines capable of eliminating the residue of the previous crop and weed seeds present on the surface of the ground. In the same way, the surface disinfection of infected soils, often the cause of early attacks by fungi and parasites, is carried out in the same way.

The weed-killer equipment works towed from the third point of the tractor during work and lifted by the same during maneuvering or transfer. This allows the equipment to constantly follow the surface of the ground, which in any case must be well leveled and prepared.

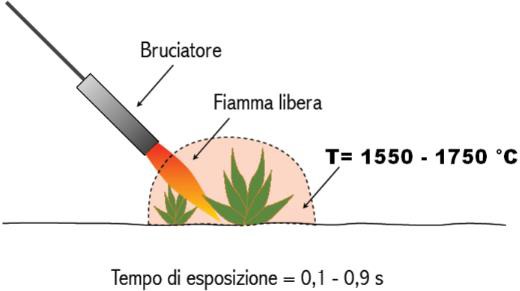

Moving the third point linkage on one side, while keeping the machine balanced, allows the tractor to follow the tracks already brought to the ground from all previous work without ever stepping on the baulature. The equipment consists of a combustion chamber containing the burners and the supporting structure. The combustion chamber is open towards the ground at the front where the burner is inserted. The burner is powered by LPG and is of the premixed type with primary air intake outside the combustion chamber and secondary air intake at the front of the chamber near the ground. The load-bearing structure is equipped at the front with two ground support wheels that can be adjusted in height by means of special tie-rods and at the rear with a roller that keeps the height of the machine constant from the ground. The heat propagates on the surface of the ground and invests the first two/three millimeters of the same causing the elimination of fungal spores and producing the sterilization effect of the seeds of the weeds. The equipment makes it possible to carry out localized weed control operations on transplanting or sowing strips without damaging or polluting the soil and therefore the operation can be repeated several times and at low cost. The use of the machine on crops equipped with biodegradable mulch, based on maize starch and/or other vegetable matter, can allow, with a single pass, to eliminate the residues of the mulch itself.

The use of the machine, therefore, allows obtaining a good production with a considerable economic saving. For the use of the equipment no hydraulic pressure tapping is required or the use of the PDF of the tractor. The heat treatments of “Pirodiserbo” and “Pirodisinfection” are sustainable and ecological agronomic techniques. The union of these two techniques today can be better defined as “Heat treatment of the soil“, a technique that uses heat to eliminate weeds, fungal diseases, bacteria, and harmful insects by means of thermal radiation generated by specific equipment represented in most cases by LPG gas burners. The combustion of LPG, with the same burned energy, compared to that of diesel and fluid fuel oil, shows the absence of particulates, a negligible presence of SO2, and a contained NOx emission.

This treatment has, as its main advantage, an absolute lack of harmful residues on the ground; in fact, LPG, by burning, forms exclusively water vapour and carbon dioxide. The principle on which the technique for the elimination of the aerial part of the weeds is based is that of tissue boiling. The effect of the heat transmitted to the lymphatic cells produces a sudden expansion of the cellular plasma, thus causing the outer membrane to rupture. The cell can no longer be nourished and the intracellular flow is thus interrupted. With this technique, the weeds are not burnt, but immediately after the heat treatment the plants show a variation in pigmentation; the green color of the leaves is strongly accentuated.

If the treatment is carried out on herbs that are in the juvenile vegetative stage (20-25 days from the emergency) heating of 90-95°C for the duration of one second is sufficient to determine their death.

In other cases, with plants in an advanced vegetative state, it is advisable to apply 101°C for the duration of one second.

From an ecological point of view, this technique is a practice characterized by a completely negligible environmental impact. Since LPG burns only from water vapor and carbon dioxide, the flame is transparent and free from any phenomenon of smoke release, any type of flooring or cladding, which is not subject to low combustion temperatures, can therefore be directly invested with the flame without even altering its color.

The heating, determined by the rapid passage of the burners, in the layers below the surface, leads to a temperature that generally does not exceed 50-60°C, a temperature that we can easily find even in the hottest hours of the summer season.

The damage to the microflora and soil micro-organisms is therefore negligible; there is no risk to operators and no release of toxic residues into the environment.

Another achievable result, from the point of view of “Environmental Disinfection” is that due to the temperature, normally slightly higher than 100°C, which reaches the surface of the ground or of the floor subjected to heat treatment with the flame. The temperature reached allows to eliminate the treated surfaces fungi and pathogenic germs, they do not resist temperatures above 70°C, allowing an effective sterilization work. With the application of this technology, the costs involved can be determined immediately since this weed-killing technique does not give rise to environmental pollution, and therefore any additional costs following treatment and due to the disposal of any toxic residues are null and void. Gas consumption is closely related to the type of equipment in use and the height of the weeds to be treated.

With the heat treatment of the soil with flame (Horticultural Crops), the drying of residues (small branches, harvest waste, crop defoliation) is carried out. Thus, in the next processing phase, fungus, spores, and residues of the previous production are avoided, as these freeze-dried residues will be destroyed by mechanical processing.

Land preparation with the Rot 1000

Rot 1000 is designed to uniformly mix the soil with the organic substance previously deposited on the surface of the soil, up to a maximum depth of 70/80 cm.

This technique makes it possible to oxygenate the layers involved in the work and at the same time to enrich the soil with organic matter. The use of this machine is important before the planting of fruit-bearing plants or crops such as asparagus, which need to bring the root systems down to important depths, allowing them to find nourishment in the soil. In the case of horticultural crops, the layer affected by this type of processing is only 40 cm. In this field, the importance of enriching the soil with organic matter is fundamental, as the repetitiveness of these crops is considerable.

This technique makes it possible to oxygenate the layers involved in the work and at the same time to enrich the soil with organic matter. The use of this machine is important before the planting of fruit-bearing plants or crops such as asparagus, which need to bring the root systems down to important depths, allowing them to find nourishment in the soil. In the case of horticultural crops, the layer affected by this type of processing is only 40 cm. In this field, the importance of enriching the soil with organic matter is fundamental, as the repetitiveness of these crops is considerable.

From the technical point of view of tillage, the characteristic feature of this machine model is that it has a high number of rotating elements, which means that it leaves no unprocessed space.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.