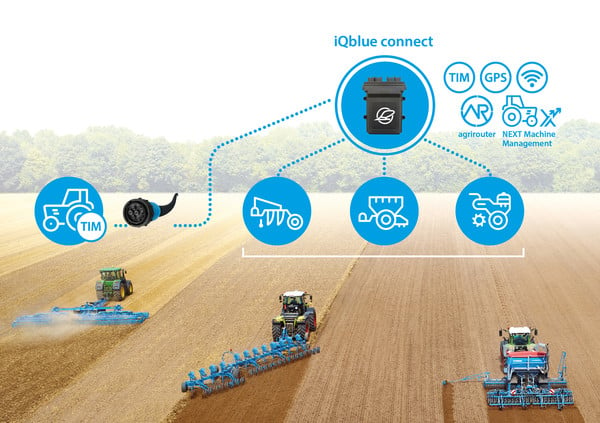

The soil becomes harder, plowing is more difficult, but the plow controls the tractor as if by magic in order to cleanly pull through the furrow with the correct working width. The new Lemken “iQblue connect” implement set, whose suitability has now been certified by the industrial organization AEF (Agricultural Industry Electronics Foundation), realizes this dream of all arable farmers. Lemken is the first agricultural machinery manufacturer in the soil cultivation segment to be awarded such a certificate by AEF.

Function

The basis for communication between the new equipment set and the tractor is TIM, a new standardized ISOBUS function. With its help, “iQblue connect”, coupled between the tractor and the attachment, can ensure an optimal work result with considerable relief for the driver. Work information from the attachment can be used for the automatic control of the tractor. If the attachment reports an increase in pulling resistance, for example, the engine power and pressure of the control valves are automatically adjusted: the implement controls the tractor!

Installation & integration

From a purely technical point of view, “iQblue connect” is a retrofit system that can be used not only with brand-new but also with many soil cultivation implements that are already in use. It is only important that the tractor and the implement support the ISOBUS standard from TIM and have a corresponding AEF certificate for this function. “IQblue connect” also has GPS for location and a mobile data connection for communication, for example with a farm management system.

Features

As an intelligent implement control, “iQblue connect” can, for example, control the working width of plows in conjunction with a TIM-certified tractor. The system determines the current GPS position and the working width of the plow and directly accesses the hydraulic control unit of the tractor via TIM in order to control the working width cylinder of the plow. This automatically keeps the furrow exactly straight. In addition, it is finally possible to plow exactly in the target furrow, which saves a lot of time when working on wedges.

With semi-mounted cultivators, “iQblue connect” allows the intensity of the tillage to be optimized. By comparing a sensor value for the current working depth with the specifications of a site-specific work card, “iQblue connect” activates the tractor hydraulics via the TIM so that the working depth of the tine field is precisely adapted to the changing soil conditions.

source: Lemken

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.