Epiroc is increasingly providing customers with groundbreaking solutions within automation, connectivity and digitalization. As this development is picking up speed, Epiroc wants to keep its customers at the technical forefront and accelerate the digital transformation in all fields of their operations.

“Automation, digitalization and electrification are transforming mining into a much safer, more sustainable and profitable business. The construction industry, all the way from tunneling and infrastructure to demolition and recycling, is moving in the same direction and we want to make sure our customers have access to the right solutions that truly meet their current and future needs,” says Helena Hedblom, President and CEO of Epiroc.

Automation functions

Big infrastructure and civil engineering projects are complex, with endless moving parts to consider. And compared to mining, the timeframes are usually much more compact. Still, a clever use of data and autonomous functions, smoothly integrated to existing operations, can optimize production without compromising productivity.

Take the Epiroc drill rigs for example. By delivering a precise amount of power for each phase of the drilling operation, all based on continuous data, fuel consumption is optimized without compromising productivity. Additionally, the optional hole navigation system (HNS), that uses positioning data and provides unmatched accuracy in basically all aspects of the drilling process, helps cut drill and blast cost considerably.

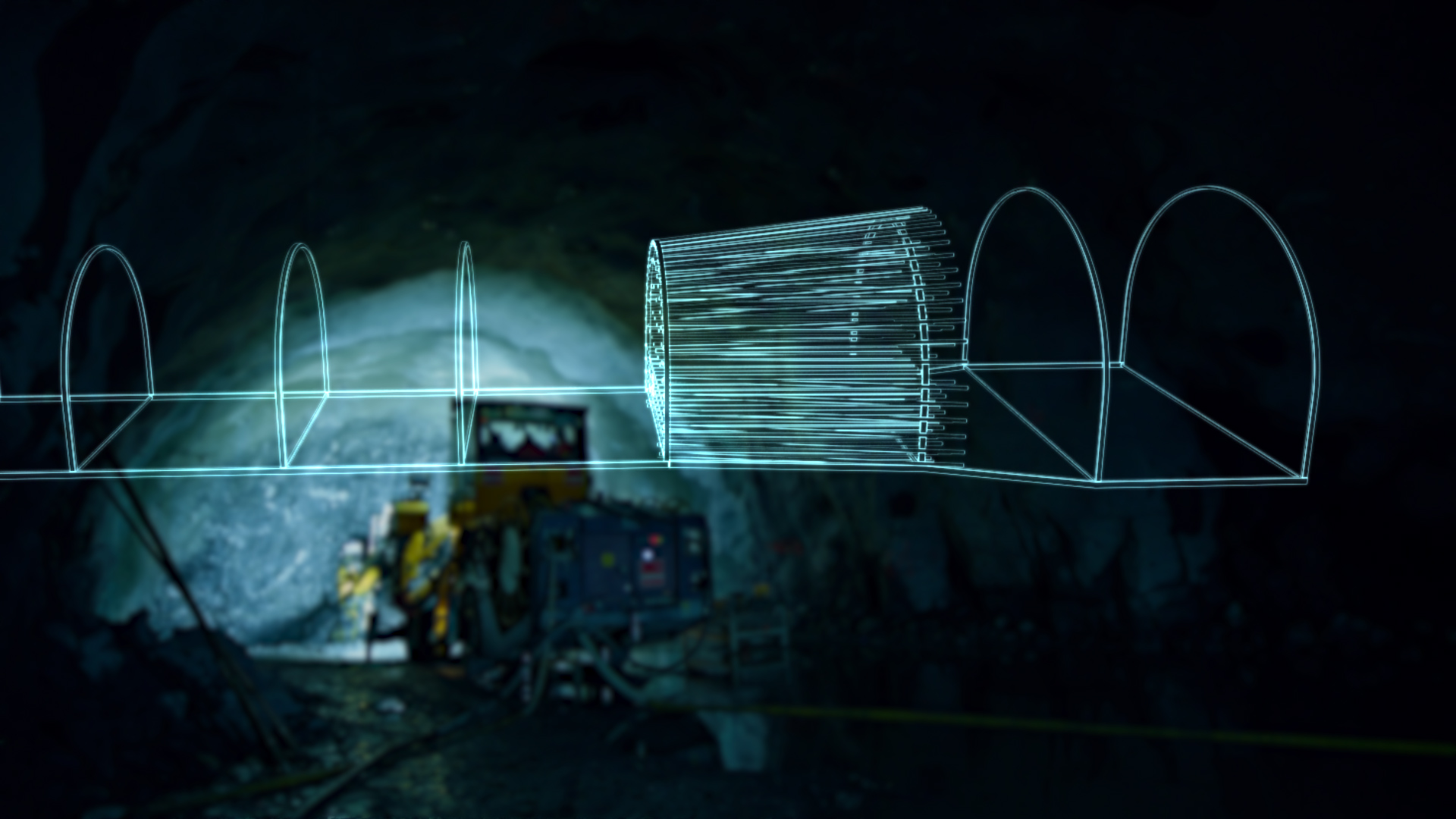

For tunneling projects, the Dynamic Tunneling Package has a similar impact. By using the existing 3D CAD model of the project, the drill rig can create its own drill plan directly on the face of the tunnel. This enables a more flexible work process that saves time and delivers a very accurate end result.

Connectivity

Making data and new technology accessible, and above all easy to use in the daily operation, is key. Hatcon, a remote monitoring device for hydraulic attachment tools, provides an overview of the entire fleet as well as status of individual tools via My Epiroc, an easy-to-use application available on any device. Service reminders minimize unplanned stops, and ordering and delivery of parts are integrated. The effects on efficiency and profitability are substantial.

Data analysis

Epiroc’s telematic solution for gathering and processing data from surface drill rigs, Certiq, gives customers a deeper look under the skin of their equipment. Position (GPS coordinates), equipment utilization and performance, fuel consumption and machine health are all accessible via a web-browser. A perfect solution for fleet management in order to monitor vital operational KPIs and plan service activities.

Experience the World of Epiroc online

Through Epiroc’s interactive virtual experience “World of Epiroc” customers can learn more about our ground-breaking solutions. Accessible from www.epiroc.com/world-of-epiroc it lets the user easily access product and service information, videos and customer case stories.

“With the new online feature World of Epiroc, we give our customers a virtual experience that showcases many of these solutions,” concludes Helena Hedblom, Epiroc’s President and CEO.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.