A continually growing global population and the desire for increased prosperity among many emerging nations are putting enormous stress on the environment and natural resources. It is crucial to move away from the current ‘take, make and waste’ linear economic model that relies on large quantities of cheap, easily accessible materials and energy.

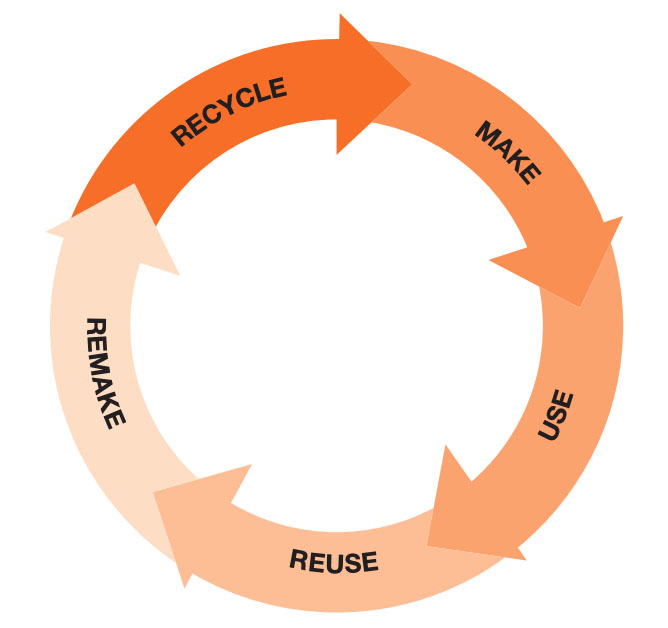

The alternative is a circular economy in which few materials are wasted, and products are not only designed and built for longevity, but also for multiple reuse and eventual recycling. As an important element of this economy, the process of remanufacturing has been growing in recent years.

Win-win situation

The construction industry is well-positioned to make a positive contribution in this area by increasing the production and encouraging the use of remanufactured parts and components – rather than simply replacing used, or worn-out items, with new ones.

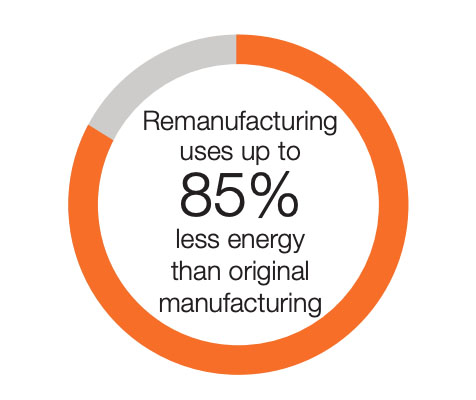

The potential benefits of manufacturers fully embracing and adopting these practices include the reduction of non-reusable waste products, helping address resource-scarcity issues, and contributing to reducing the environmental impacts of industrial activity around the world.

For equipment owners, deciding to use remanufactured parts offers an affordable and sustainable alternative (to buying new) without compromising on quality.

Meeting the challenge

The challenge for any manufacturing industry is how to extract the maximum value from machinery and parts while they are in use while being able to recover and regenerate most of these products and materials at the end of their initial service life. Hitachi Construction Machinery’s response to this challenge is to offer an affordable, premium repair solution, known as Hitachi Remanufactured.

Just like new parts, remanufactured components will keep a Hitachi excavator, wheel loader, or dump truck operating optimally, as they are tested and made to the same exacting specifications.

Remanufactured components also come with a Hitachi warranty, but are more affordable than new parts. They are designed to lower operating costs and minimize unscheduled downtime, so they are a good choice for preventative maintenance, or to get back up and running as soon as possible.

Sustainably leading the way

A used part can be easily and quickly exchanged for the corresponding remanufactured component at a local Hitachi dealership, which will return it to one of Hitachi’s dedicated centers to be remanufactured to the same high standards as new components. Once finished, the part is then ready to go to another Hitachi customer, complete with a comprehensive warranty.

The remanufacturing process allows Hitachi to lower waste and save resources by reducing the need for raw materials. It has the added benefit of being better for the environment as the ‘core’ product is rebuilt and then supplied back into the market.

Here and now

The global roll-out of parts remanufacturing in construction machinery will not only contribute to helping achieve a resource-efficient industry sector but also offer owners an affordable and sustainable way of keeping their machines working.

Furthermore, a machine’s life can be extended without compromising on quality but with the peace of mind provided by a comprehensive Hitachi Remanufactured warranty.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.