This year we celebrate the 75th anniversary of the Cat dozer blade. Some say it may be the ultimate part provided by Caterpillar to its customers. Yep, the dozer part. The term “dozer” originally referred to a steel plate and an operating mechanism attached to the front of track-type tractors. Today, the term also refers to the rugged machines built for tough jobs pushing dirt.

1945 is a date that returns to the memory of many. It was also a decisive year for Caterpillar, which started developing its own line of bulldozer blades in 1945.

Before that date very little on the market. Until the 1800s, dozer blades were crude by any standards. They were made of wood and affixed to the front end of a pole that was pulled by horses or oxen. Their main purpose was to spread loose dirt out over a fill as it accumulated.

In 1914 the Holt Manufacturing Company, one of Caterpillar’s predecessor companies, introduced a dozer blade in front of the machine that was controlled by a rope windlass fastened to the tractor’s main frame. They continued to make dozers in small quantities until they were discontinued after their merger with the C.L. Best Tractor in 1925.

A LEGEND IS BORN

In 1945 Caterpillar began manufacturing straight, angled and U-shape bulldozer loaders in both cable and hydraulic options. And then the first Caterpillar tractor with the new dozer blade left Peoria, Illinois. Performance, improvement, testing and engineering developments continued throughout 1945 at the new companies in Illinois and Arizona. Caterpillar’s reputation was already high enough to ensure the success it has today.

First shipments of Caterpillar track-type tractors with accompanying Caterpillar dozer blades were made later that year. The Caterpillar track-type tractor quickly became known as a “dozer” and the legend was born. These machines worked on some of the modern world’s greatest engineering projects, including the U.S. Interstate Highway System, the Three Gorges Dam in China, and the widening of the Panama Canal, just to name a few.

The advancement of technology in the modern world led to the introduction of cable control systems, with only upward movement, and then to hydraulic systems, which were easier to use than the former and could lift or push down. The advancement of technology in the modern world led to the introduction of cable control systems, with only upward movement, and then to hydraulic systems, which were easier to use than the former and could lift or push down.

Today it is not uncommon to hear about a dozer blade as a “tractor”. This credit came from the widespread use that was made of it during the Second World War, so much so that it was considered “the indispensable and versatile weapon of engineers”. The dozer (also called a bulldozer) was not the tractor, but actually the steel plate and operating mechanism, made by a supplier, that was attached to a standard Caterpillar track-type tractor. American Admiral William F. Halsey once said,

“If I had to give credit to the instruments and machines that won us the war in the Pacific, I would rank them in this order: submarines first, radar second, planes third, bulldozers fourth.”

TODAY’S DOZER

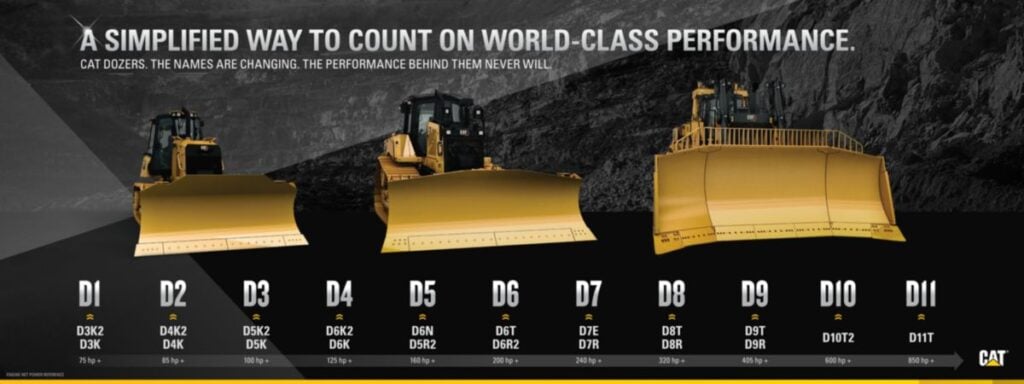

The Cat bulldozer is today one of the most popular and versatile machines on the market in its category. Cat Command’s option for dozing is a technology that today helps increase operator safety, comfort and productivity. The Cat Command for dozing makes remote and semi-autonomous operations of these machines possible. Whether you are moving material or classifying finishes, small, medium or large, there is a Cat bulldozer made for this.

The Small line (D1-D3) is perfect if you are looking for a quick work partner when moving from one site to another in versatile construction work. With the right combination of speed, power and precision and the new GRADE technology, Cat Small bulldozers are a valuable small dozer on the job site!

Medium Cat (D4-D7) bulldozers offer industry-leading fuel efficiency and ease of maintenance that reduce ownership and operating costs. The new generation models all feature the industry’s first high-speed electric transmission in this size class and factory integrated Cat Grade technology. This line also boasts high versatility of performance: the choice of powertrain and dozer blade configurations allows customers to adapt the machine to the application, whether it is a large bulk earthmoving precision levelling job.

Large Cat dozers (D8-D11) are built to take on the world’s most demanding work. Elevated sprockets increase productivity, simplify maintenance, reduce downtime and raise final drives and powertrain components out of tough underfoot.

Source: Caterpillar

![[Video] New Generation DAF Trucks in ‘Construction Simulator’ Game](https://www.heavyquipmag.com/wp-content/uploads/2024/12/DAF-trucks-218x150.jpg)

![[Video] How a Huge Mining Excavator Can Be Electric](https://www.heavyquipmag.com/wp-content/uploads/2025/01/liebherr-r9400e-fortescue-218x150.jpg)

![[Job Story] New Develon DD130 Dozer at Work in Portugal](https://www.heavyquipmag.com/wp-content/uploads/2025/01/Joel-Pereira-Administracion-CS-Retail-Construcoes_red-218x150.jpg)

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.