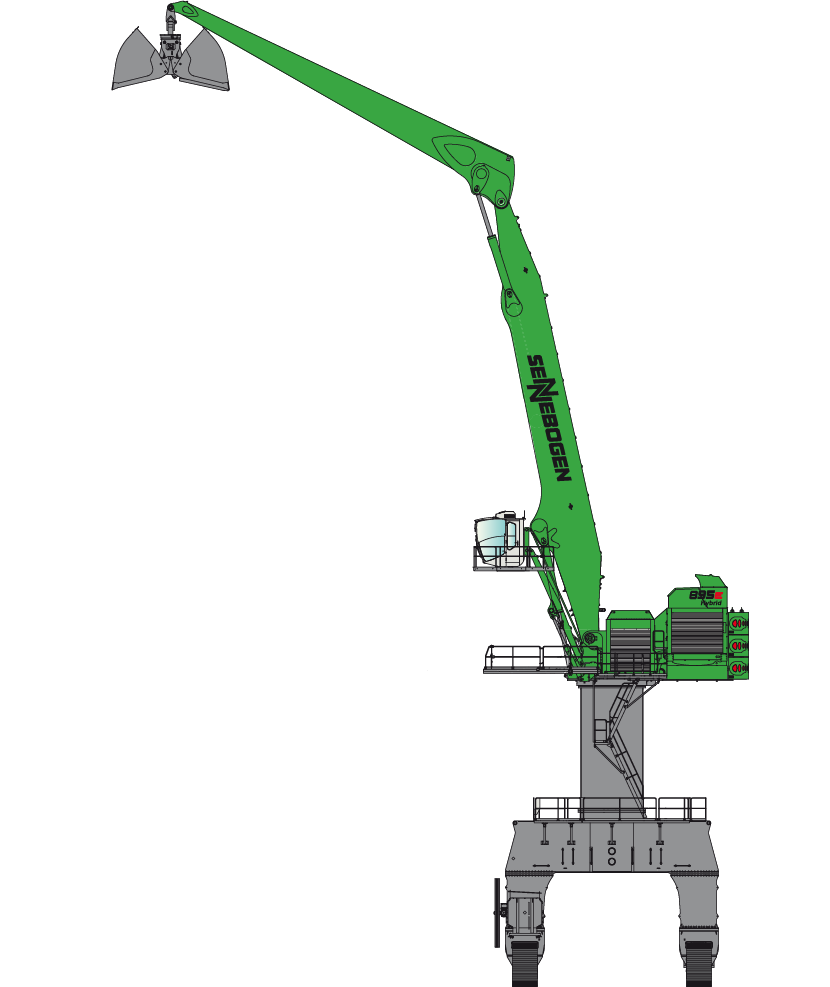

Since October 2019, a gentle giant from SENNEBOGEN has been moving masses of old scrap every day and in the shadow of the enormous port machine. The largest material handler in the world, launched at bauma 2019, is now an integral part of port operator Tosyali’s green fleet.

The E SENNEBOGEN 895 is definitely making a difference in Tosyali Holding’s port of transshipment and continues to move tons of steelwork. Commissioning by Turkish sales and service partner Forsen Machinery, its Weighs is 420 tons, 500kw electric motor.

The machine does not use diesel: it is equipped with the Green Hybrid system for maximum energy savings of up to 55%. On the other hand, maintenance frequency is significantly reduced and the overall wear and need for replacement parts including transport costs is significantly lower on electric machines than on their diesel counterparts.

“Our experience with SENNEBOGEN machines has shown us that using electric material handlers does not mean compromising on flexibility or speed,”

explains Harun Karaarslan, Technical Port Director at Tosyali.

Tosyali Holding’s transhipment port, located in one of the largest metal producing areas of Turkey, supplies the local steelworks with scrap, among others. Boasting a net weight of around 420 t and a 500 kW electric drive, the SENNEBOGEN 895 E-Series is the central linchpin of the specialist port’s fleet. Despite its remarkable size, the machine works quickly, efficiently and without emissions.

The port giant’s boom has two in-built hydraulic systems that compensate for the dead weight of the 53 t steel structure. Along with the hybrid storage modules installed on either side of the machine right next to the boom pivot point on the uppercarriage, they make up SENNEBOGEN’s Green Hybrid energy recovery system. Like a spring, gas is compressed in separate gas cylinders, storing energy that can then be used during the next lift. This subsequent lifting motion is just like the spring being released and the energy from the compression being let out again.

One of the fundamental requirements that led Tosyali to choose S E 895 is its high performance capability at high altitude. The operator can raise the large port cab up to a height of 22 m thanks to the Skylift cab elevation. This helps with the placing of bulk goods and cargo in ships’ hulls and makes unloading freighters much easier, not to mention the fantastic panoramic view of the port. The operators are supported by additional cameras at the rear and on the right-hand side of the machine, conveniently observable via a screen in the cab. There is also the option of installing a camera on the stick of the 40 m long equipment which makes placing or grabbing materials in ships’ loading areas much easier.

“We handle 10,000,000 tons a year in this port alone, our machines are in constant use. We are reliant on the machines in our fleet working constantly, downtime would be fatal,”

Tosyali is currently using the machine to unload scrap. A 12 t orange peel grab with a capacity of 10 m³ is installed on the stick. In the future, a wide range of bulk cargo will also be handled with a clamshell grab. Thanks to the green giant’s sensitive controls, the grab moves gently over the hopper and loads up the waiting trucks in a cycle time of around 40 seconds.

Source: Sennebogen

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.