Alex Lundgren, product manager, Global Crop Care, Seeding & Tillage at AGCO says:

“Row crop producers know an evenly emerged, picket-fence stand planted during the ‘ideal planting window’ is a critical first step for optimum yields. However, at planting, there are many agronomic and operational challenges that can be beyond their control. That’s why it is important to control what we can, when we can.”

Rex Schertz, engineering manager, Seeding & Tillage at AGCO, says:

“Providing producers greater control at planting is why AGCO has developed the Fendt Momentum planter delivered with AGCO-exclusive SmartFrame technologies”

The Fendt Momentum planter is a global platform, created from a clean sheet and capable of planting a wide array of crops in varying conditions around the world. Designed by a global engineering team, the planter will be built in Beloit, Kansas, for North American producers. The Momentum planter is easily customized with popular and industry-leading technologies from Precision Planting, making it sophisticated yet simple to operate.

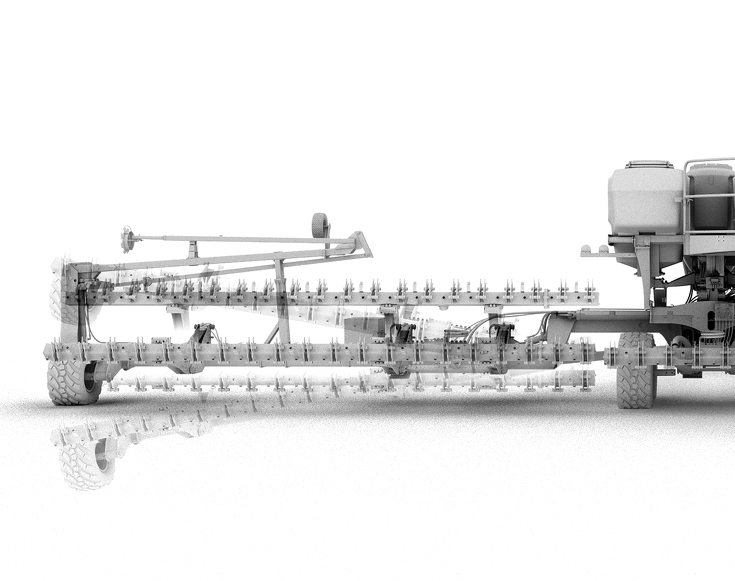

Innovative secondary toolbar evens planting depth

SmartFrame innovations set this planter apart from other planting technologies. Notable is its vertical contouring toolbar, configuration, and smart, automated capability.

This new planter is made up of three independent, intelligent sections that operate automatically, ensuring the row units on each section maintain the ideal seeding depth. The planter’s patented sensor-controlled hydraulic system monitors the angle of the row-unit parallel arms to automatically adjust toolbar height, keeping the arms level and the row units properly engaged with the soil as ground conditions and terrain change.

The vertical contouring toolbar flexes up and down as much as 68 inches to follow the contour of the field and ensure the row units properly engage with the soil.

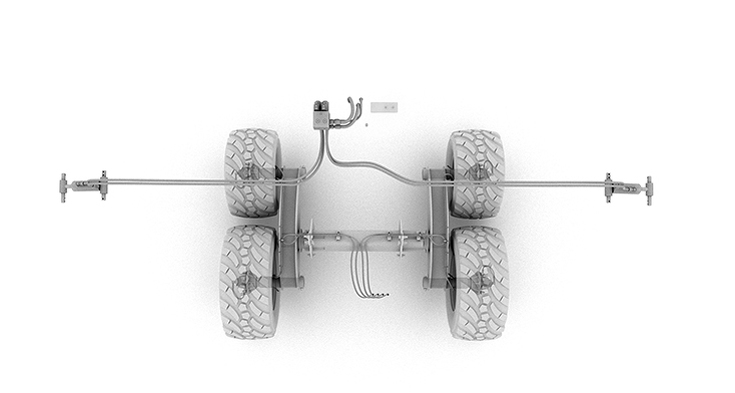

Wheel placement, tires, and inflation system eliminate pinch rows and reduce soil compaction

The second engineering is wheel placement. While high-capacity, central-fill seed, and fertilizer on many planters offer a time-saving advantage, the added weight creates challenges and contributes to issues such as pinch rows and soil compaction. Instead of side-by-side duals for center transport, wide in-line tandem wheels travel in front of the row units, eliminating pinch rows.

The wheels are positioned in the same path as the tractor tires, limiting compaction. The in-line tandem wheels also provide the flotation advantage of tracks and the high road speed of tires.

Wing wheels can be placed according to customer preference but are typically on the end of each wing, to run outside the last row-unit. This puts wing wheels in the same path on each pass through the field, reducing overall compaction without sacrificing row numbers or spacing. In addition, the Momentum planter is equipped with VF, or “Very High-Flexion,” tires that have a large footprint and carry 40% more weight at the same inflation as conventional radial tires.

Automated weight management system option

for minimizing compaction

The third differentiating technology is the optional weight management system. It can be equipped with a central tire inflation system that automatically adjusts tire pressures from the roadway to the field, deflating the tires as the wings unfold. To reduce yield-robbing soil compaction during planting, the system will automatically adjust tire pressure up or down compensating for the fluctuating weight of the planter as seed and fertilizer are used or replenished. The system reduces each tire’s pressure to the lowest field setting as suggested by the tire manufacturer for the weight present at any given time, down to the pre-set low of 15 psi.

Operators can select from two automated modes. The Load Balance mode equalizes the weight across the planter, adjusting based on weight and speed information from sensors on each axle. Without such a system, traditional central-fill planters can cause an 11-bushel/acre loss in corn yield from wheel-traffic compaction in the center vs. wing rows, according to research from Pioneer.

The Controlled Traffic mode transfers the bulk of the weight to the center section of the planter, practically eliminating the weight on the soil from the wing tires. By concentrating the planter’s weight in the tracks made by the tractor, soil compaction is limited. This mode works well for growers who maintain tram lines and use the same path for each field operation.

Planting-time efficiency and speed

The Momentum planter is built for efficiency and speed in the field, between fields and when changing crops. It carries large volumes of seed and fertilizer with twin seed tanks that hold 65 bushels each, while the fertilizer tank holds 1,000 gallons of liquid for more acres planted between fills.

When equipped with the optional SpeedTube seed tubes from Precision Planting, Momentum will operate at up to 10 mph ‒ twice the conventional planting ground speed ‒ with more than 99% singulation and seed-spacing accuracy when planting. Changing from 15-inch row spacing to 30-inch spacing can be done in record time, thanks to splitter rows that hydraulically rise and lock up based on planter configuration choices made on the in-cab monitor. A single touch folds and unfolds the planter automatically and simultaneously activates the tire inflation system.

“We’re very excited about the Momentum planter’s agronomic benefits and what it can do for North American producers. We invite producers to come to see the planter for themselves”

Source: Fendt

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.